Additively manufactured flow reactor for improved performance, safety and sustainability of chemical processes

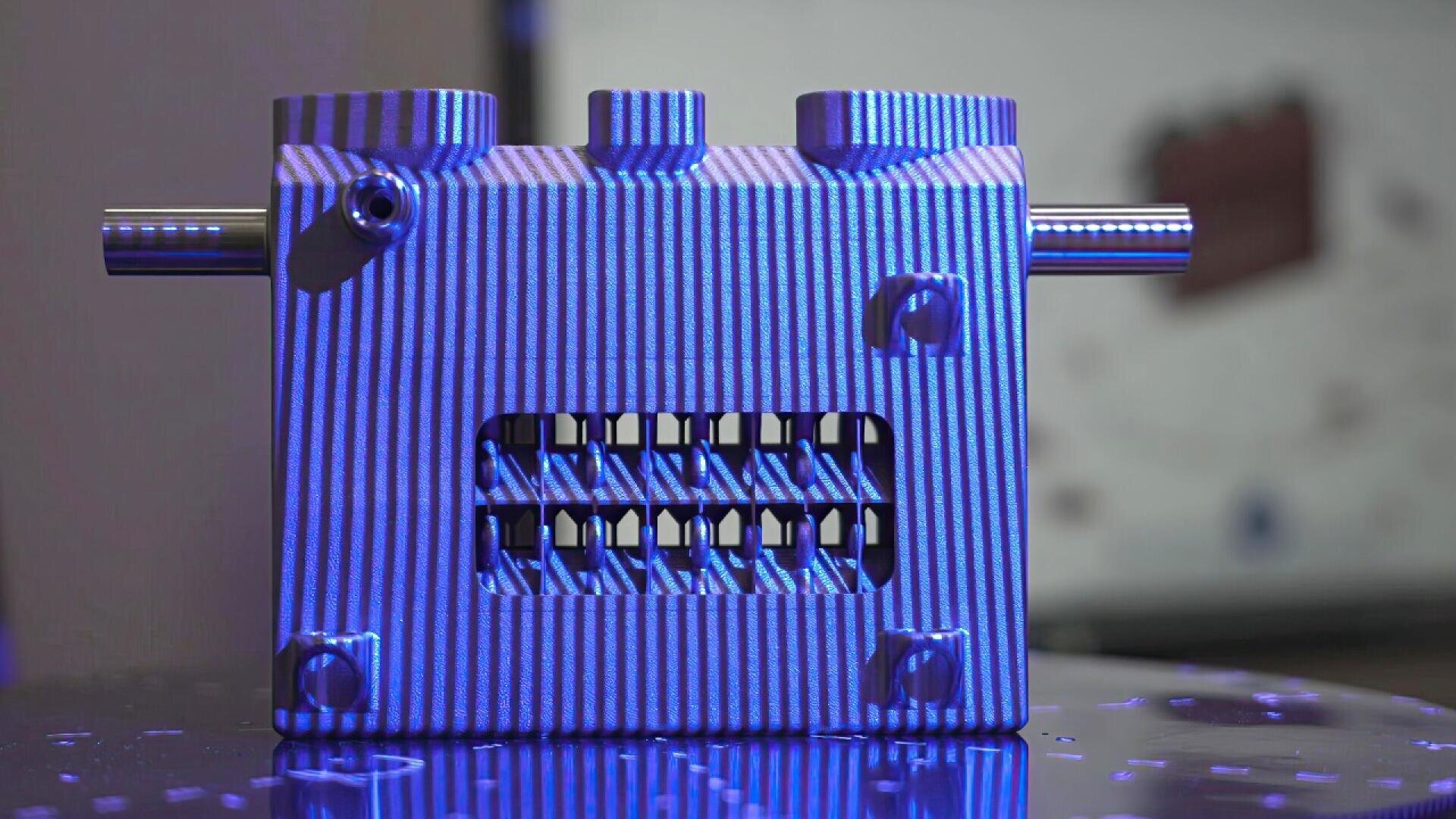

To ensure the safe development of chemical processes with hazardous and fast reactions, InoSyn relies on continuous flow reactor processes as a key technology. toolcraft was able to additively manufacture these state-of-the-art reactors with precision.

The starting point: Expanding the range of flow reactor features

To safely develop chemical processes that involve dangerous and rapid reactions, InnoSyn relies on continuous processes in flow reactors as the key technology. Using experimental, theoretical and simulation-based approaches, the company has developed advanced reactors in-house that can handle challenging chemical processes safely, thanks to complex geometries and integrated sensors. These innovative designs far exceed the options available from conventional manufacturing processes. With toolcraft, InnoSyn has found a partner who can deliver these ultra-modern reactors with precision, using additive manufacturing. toolcraft is approved as a material manufacturer in accordance with the Pressure Equipment Directive (PED) 2014/68/EU, so the high-load components it manufactures can be used for industrial applications.

The challenge: Complex processes for an optimal result

First, toolcraft had to successfully complete the process of becoming certified as a material manufacturer, which requires a high level of professionalism in areas such as material characteristics, the quality management system, documentation and communication with notified bodies. How the manufactured components can be qualified and what documentation is required for qualification also had to be defined.

The design was thoroughly validated by simulations, which was necessary because of the complex internal structure. The goal was to increase productivity compared with conventional batch processes while also ensuring that the reactor could scale to meet different production requirements. Given the corrosiveness of the reagents, an alloy was selected with exceptional strength, thermal fatigue resistance and corrosion resistance, even at high temperatures. Processing the Hastelloy® C22 powder was an additional challenge. An intelligent powder removal strategy needed to be developed for the complex internal structure of the component.

The approach: Combining areas of expertise

- Experiments and data analysis at InnoSyn

- Reactor designs including sensor connections and cooling channels with CAD, from InnoSyn

- Optimisation of the design using CAD and simulation software, working with InnoSyn

- Fluid dynamic and strength simulation of the reactor design with support from Siemens

- Selection of materials that meet the specific requirements

- Parameter development for LPBF manufacturing

- Manufacturing of prototypes at smaller volumes for test purposes

- Preparation of a material specification

- Certification in accordance with the EU Pressure Equipment Directive (PED)

- Production of the reactor using additive manufacturing

- Final machining of the reactor

- Quality assurance and creation of the necessary documentation

- Assembly of the individual components and approval as pressure equipment by InnoSyn

The results: Impressive improvement in productivity and energy consumption

The reactor was successfully scaled up for the specific process by using an innovative design and thanks to the synergy of chemistry, additive manufacturing (AM) and simulation. The new reactor achieved an impressive 3,000-fold increase in productivity and a remarkable 1,700-fold reduction in dwell time compared with conventional batch processes. This further development means a potential reduction in energy consumption of up to 65%. Using custom reactors manufactured by toolcraft therefore does not just improve process development. It also shows how innovative design and advanced manufacturing processes can transform the chemical industry and make it safer, more efficient and more sustainable.

Fancy more exciting case studies or technology projects? Read more on our website!