Effective and Sustainable Component Optimization Based on Additive Manufacturing

In addition to the material Polyamide 12 (PA12), SPÄH also offers a special combination of Multi Jet Fusion (MJF) technology and the material Polypropylene (PP)

Bookmark

Various companies are now leveraging the unique advantages of additive manufacturing and collaborating with SPÄH to design their custom, seamless components—free from geometric limitations.

The notion that additive manufacturing is only suitable for prototyping is long outdated. Today, depending on the component, quantities of 20,000 to 50,000 units per year are entirely feasible. Thanks to this dynamic process, design modifications can be made even during series production with minimal effort. 3D printing eliminates setup and tooling costs, which is a significant advantage. Additionally, the material properties of additively manufactured parts are fully comparable to those produced using conventional manufacturing methods. Depending on the selected material, the final product can be weather-resistant, UV-stable, durable, and impact-resistant.

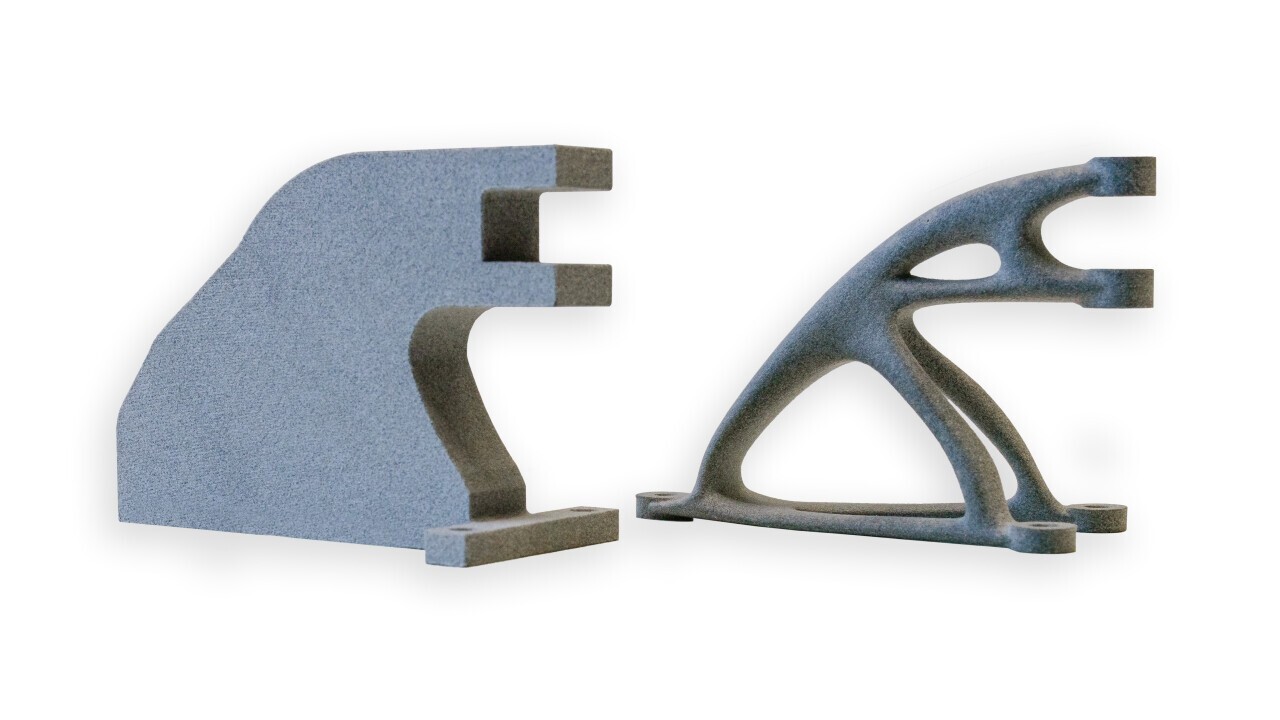

Another key advantage of this manufacturing method lies in design optimization. In customer projects, SPÄH has achieved material savings of up to 50% and weight reductions of up to 60% through design refinements and material substitutions—while improving functionality and maintaining stability. As a result, components became 30-50% more cost-efficient on average.

Furthermore, companies are facing increasing pressure to produce more sustainably. One way to reduce the carbon footprint in the long term is by shifting to additive manufacturing. This method inherently incorporates sustainable principles: for example, excess base material is 100% reused by blending it with new material. Other sustainability benefits include regional sourcing, shorter lead times, reduced transportation distances, and minimized inventory through on-demand production.