Technical Deep Dives Tour: Fraunhofer IWU - Innovative LPBF process development for new materials in thermal management

The further development of the LPBF process (Laser Powder Bed Fusion) for the processing of innovative materials with outstanding properties opens up promising prospects for thermal management.

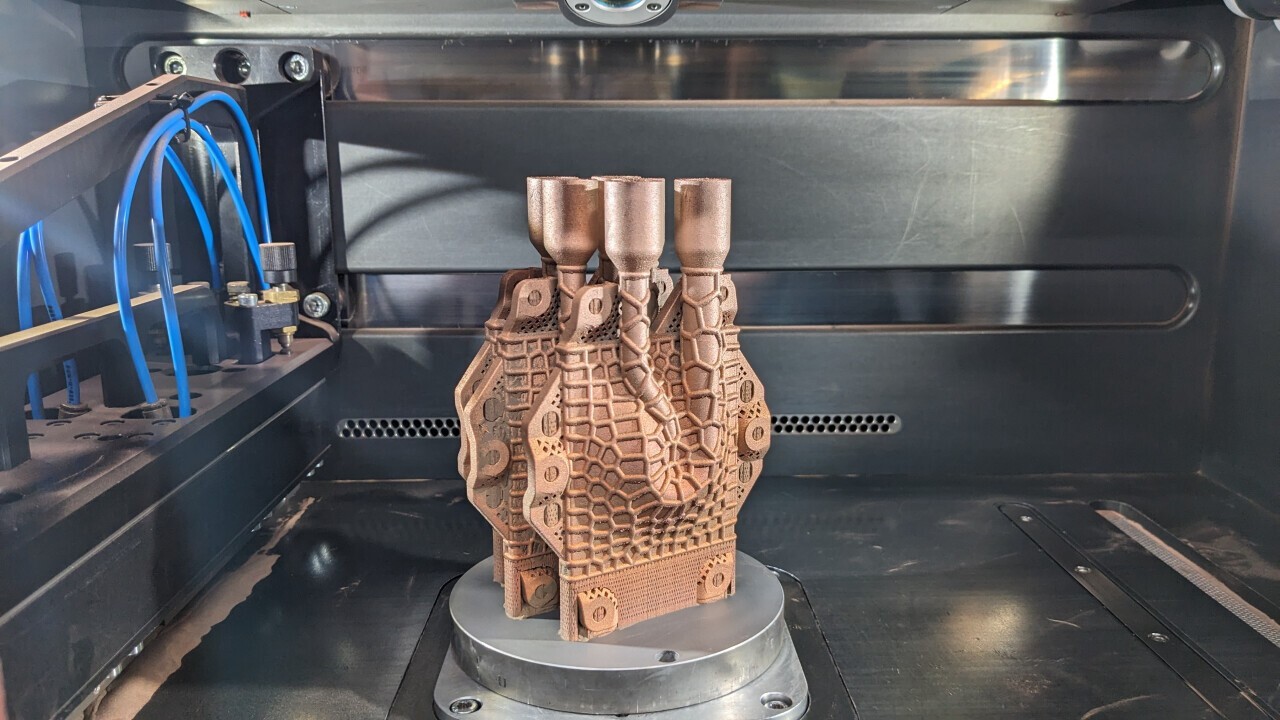

By specifically influencing and precisely controlling the melting process, specific material combinations and microstructures with improved electrical and thermal conductivity can be produced. This is particularly important for the production of components that are exposed to extreme temperatures or rapid temperature changes, such as in the energy and aerospace industries.

New metal alloys or composite materials that are processed using LPBF can not only improve thermal conductivity, but also increase the mechanical strength and service life of the components. Examples of this include thermally conductive housings, thermally optimized components in electrical devices or high-performance heat storage materials. Additive manufacturing enables the implementation of complex, high-performance geometries that cannot be realized using conventional processes. The LPBF process therefore enables the development of customized thermal management solutions that significantly improve the performance and service life of devices and systems.