3D Printing of Ceramics for Membrane Reactors

Membrane reactors are an important technology in the chemical industry. 3D printing of ceramics offers a freedom that is not possible with conventional manufacturing processes. WZR has all commercially available 3D printing processes in-house in order to compare their advantages and disadvantages.

Bookmark

Membrane reactors have the potential to facilitate the execution of industrial processes in the absence of crude oil and natural gas. While contemporary refineries continue to represent state-of-the-art technology, membrane reactors have the capacity to produce fundamental materials such as ethylene, or to generate synthesis gas from CO2 and H2.

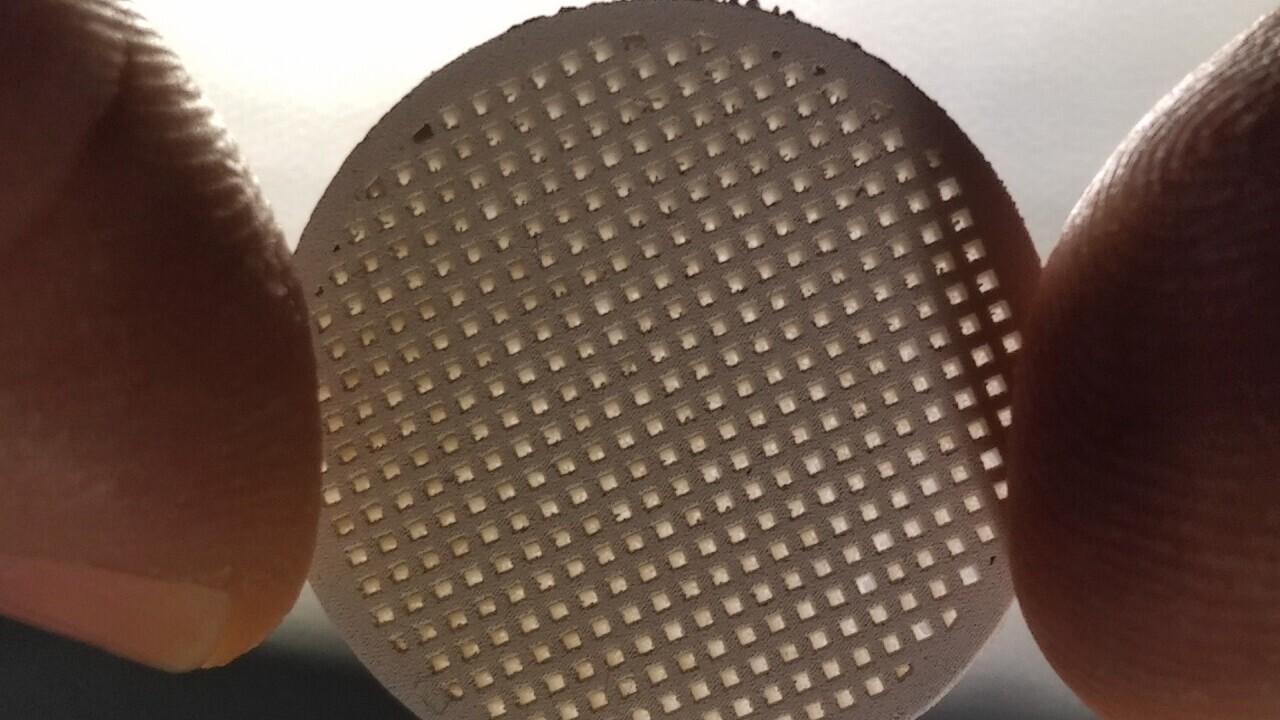

In the context of the AMAZING project (Additive Manufacturing for Zero-emission Innovative Green Chemistry), the objective is to manufacture and evaluate ceramic membranes and catalysts for such reactors. The presentation will provide insights into the project, as WZR is responsible for the eponymous part of the project, namely 'Additive Manufacturing...', the focus is on 3D printing of functional ceramics. Different 3D printing processes are compared with each other to manufacture ceramic components. The differences between the 3D printing processes are demonstrated on the basis of physical and microscopic analyses and finally compared with conventional manufacturing processes for ceramics.

Presentation language: GER

Speakers (1)