A Data-Based Certification Approach for Additively Manufactured Metal Aircraft Components

-certification platform -data-based quality assurance

Bookmark

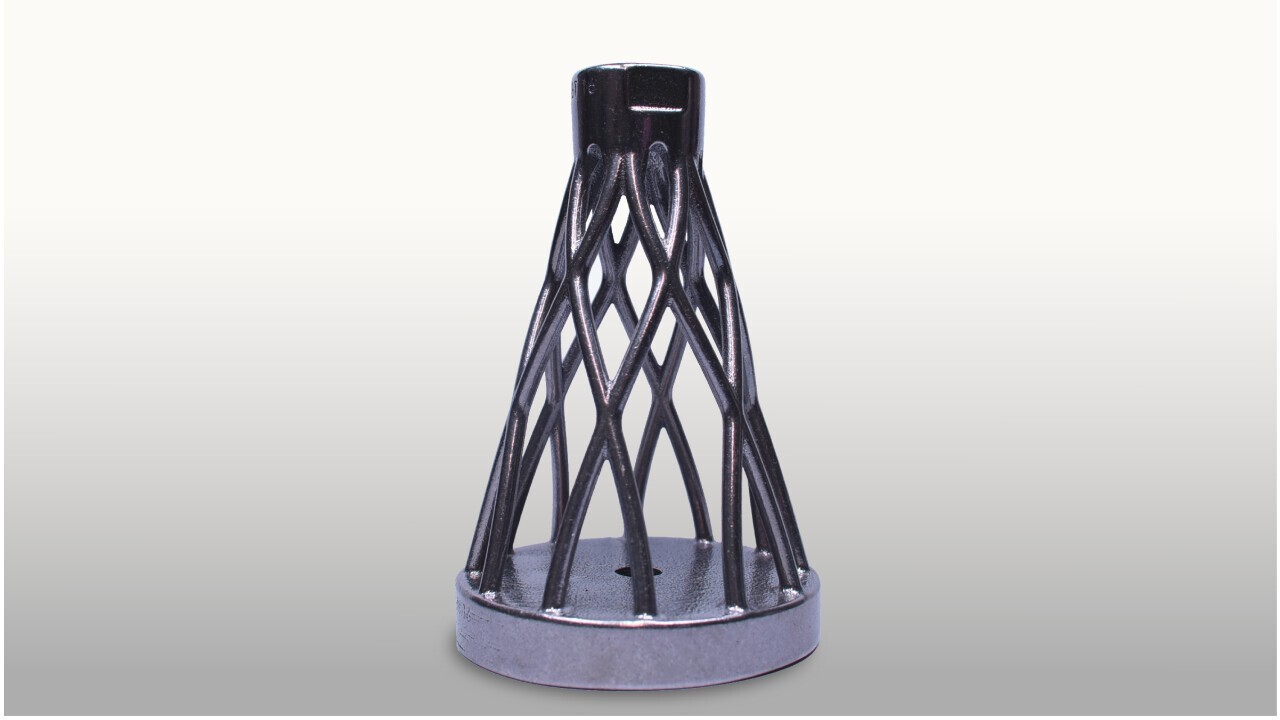

The aviation industry is changing towards more sustainable production, maintenance and operation of aircraft. In addition, new and diversified aircraft are being developed. Additive manufacturing is a suitable way of meeting the resulting requirements. Due to the many process parameters of additive manufacturing, which determine the component properties, certification for aviation is challenging. A digitalized process in the form of a platform is therefore presented for the certification of metallic, additively manufactured aircraft components. A key component is a new approach for data-based quality assurance. This takes into account all data available during the manufacturing process, such as design, production and post-treatment data. Machine learning algorithms are used to predict the resulting component properties. They are trained using the results of non-destructive and destructive tests. The test specimens required for this were manufactured from AlSi10Mg using the LPBF process. Data-based quality assurance in a productive environment only requires non-destructive analysis and process data to assess component quality. This gives all parties involved easy access to the digital certification process, including the innovative, data-based quality assurance process. Services required as part of the certification process can be triggered via the platform and results data (e.g. analysis results) can be processed digitally.

Presentation language: GER

Speakers (1)