AM Heat Exchangers for Demanding Applications: Challenges and Opportunities from Technology to Certification

This presentation addresses the advantages of additively manufactured heat exchangers and the challenges of the approval in the context of the Pressure Equipment Directive.

Additive manufacturing (AM) technologies are revolutionizing the design and production of heat exchangers for demanding applications in industries such as aerospace, energy, and process engineering. The freedom of geometric design enables the creation of highly efficient, compact, and customized heat exchangers with optimized thermal performance and minimal material usage.

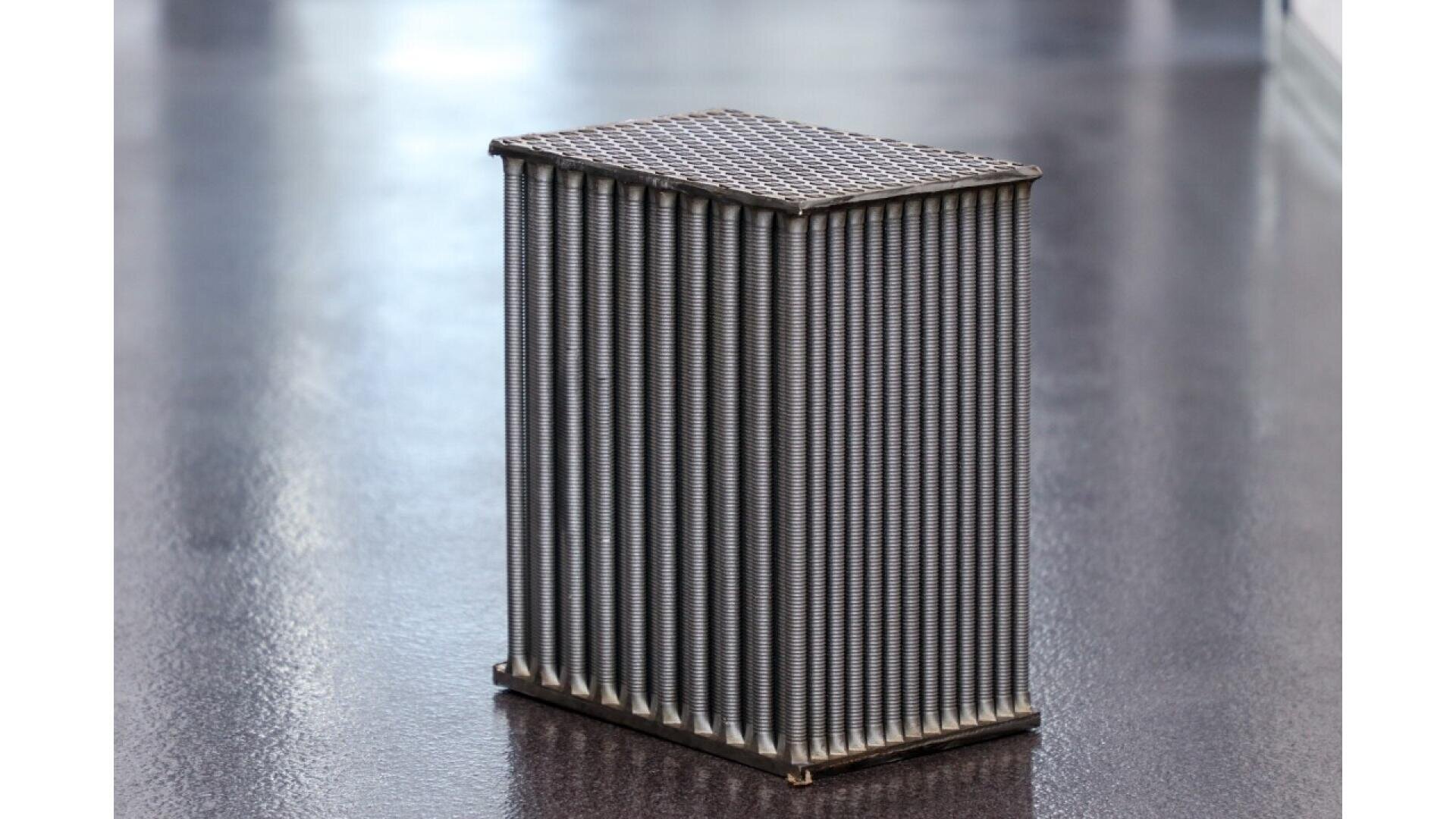

This presentation explores the technological, process-related, and regulatory challenges associated with the use of AM in heat exchanger manufacturing. It highlights the joint development of HPEX® modules by Hülsenbusch and Rosswag within publicly funded research projects, illustrating the design evolution and numerical and experimental comparisons with conventional heat exchangers. A particular focus is placed on the qualification and certification of AM heat exchangers in the context of the European Pressure Equipment Directive (PED 2014/68/EU). The pathway from the initial concept to a certified pressure device is demonstrated using the heat exchanger as an example.

Practical case studies from industry and research showcase the successful implementation of these technologies and provide insights into future developments.

Presentation language: GER

Speakers (1)