Application of additive manufacturing for fuel cells and electrolyzers

3D printing shows its strengths particularly in small quantities, fast processes and the generation of unique selling points. It is precisely these attributes that are at the forefront in the production of fuel cells and electrolysers, especially their bipolar plates.

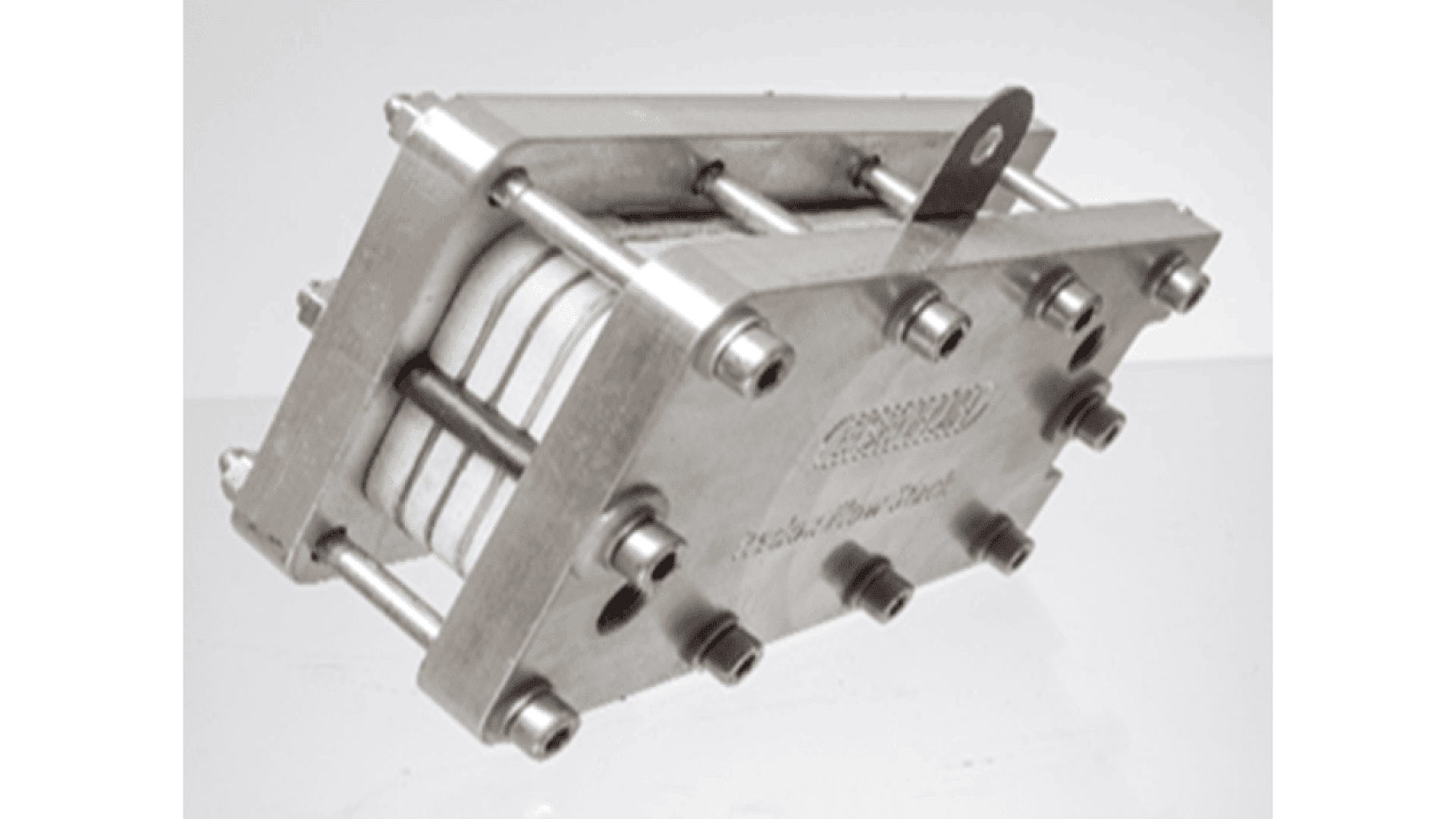

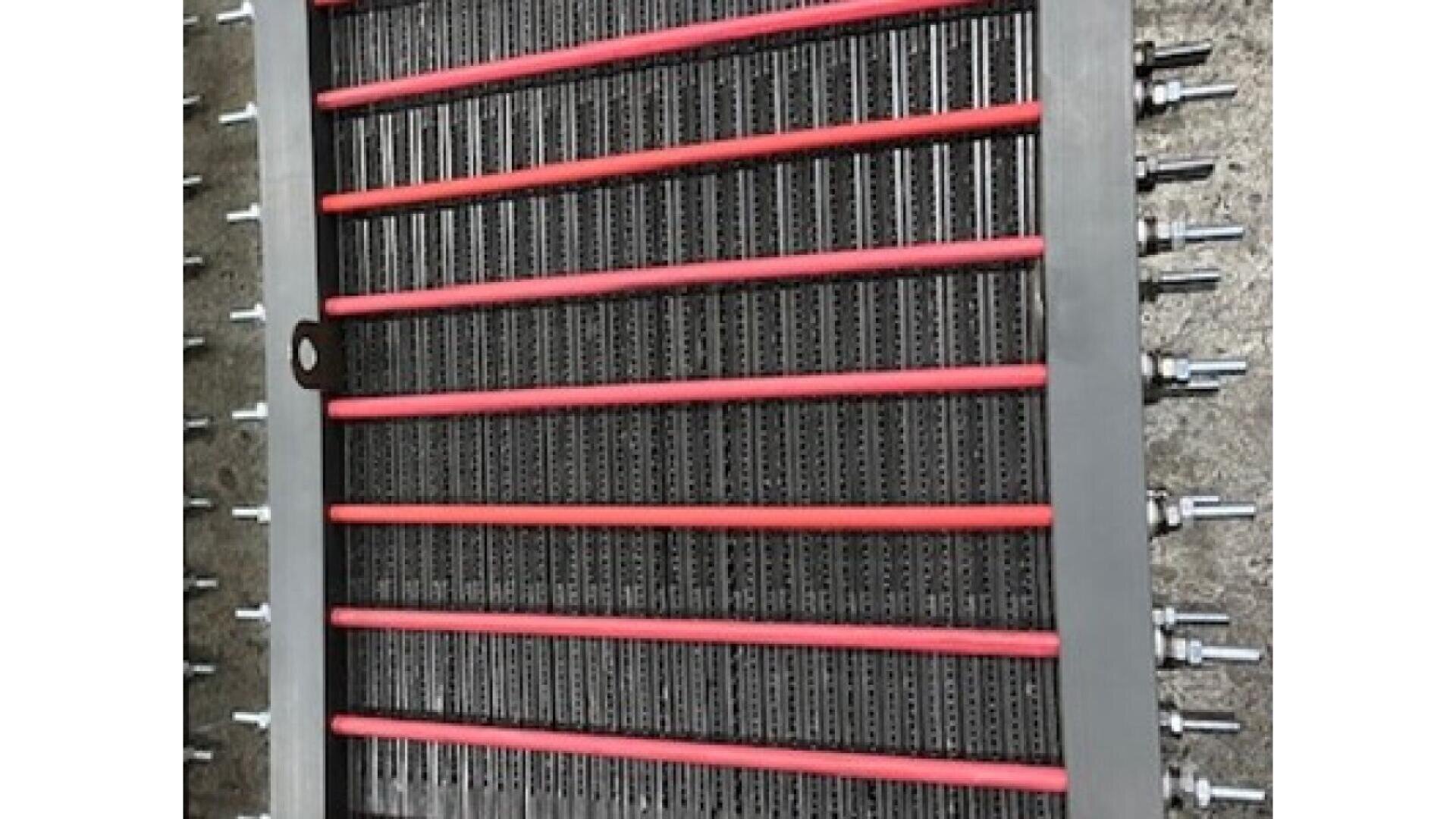

3D printing shows its strengths particularly in small quantities, fast processes and the generation of unique selling points. It is precisely these attributes that are at the forefront in the production of fuel cells and electrolysers, especially their bipolar plates. Adapted 3D printing processes such as screen printing allow preliminary products to be manufactured faster and in significantly shorter product development cycles, resulting in products that perform significantly better and also offer a new form of protection against product piracy. In the area of biploar plates, the focus is particularly on impermeability and electrical conductivity, two properties that are not necessarily associated with 3D printing and can now be implemented in the material-process-rework and QA process chain in conjunction with the adaptation of the 3D printing process for screen printing. This results in applications that are not necessarily obvious in the fields of electromobility, hydrogen, fuel cells and electrolysis.

Presentation language: GER

Speakers (1)

Dr. Eric Klemp

Head of Fuel Cell and Additive Manufacturing Department by Whitecell Eisenhuth