Deep learning and advanced analysis for automated defect detection on AM-parts.

1. AI-Powered Defect Detection 2. Enhanced Accuracy & Consistency 3. Automated Reporting & Compliance 4. Cost Reduction & Scalability 5. Statistical Process Monitoring 6. Real-World Application

Bookmark

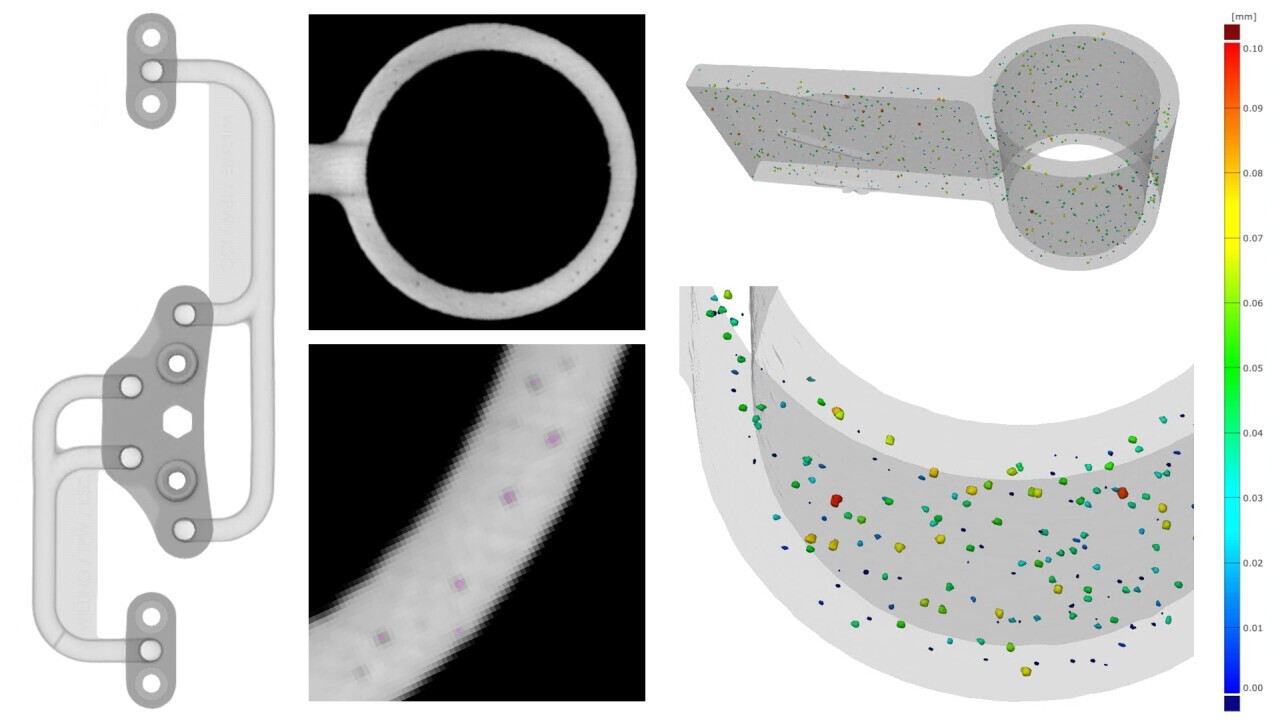

In this talk, we explore how deep learning and advanced analysis revolutionize automated defect detection in high-end CT scans of additively manufactured (AM) parts.

By leveraging AI-driven segmentation and classification, our approach detects and evaluates defects — such as pores — with unmatched precision and consistency, surpassing human capabilities in manual inspection. Detected flaws are automatically assessed against predefined specifications, generating comprehensive inspection reports without human intervention. This not only enhances reliability but also significantly reduces inspection costs for larger production runs.

Beyond individual part analysis, this method enables statistical process monitoring by building a database of inspection results, providing valuable insights into production trends and quality control. We illustrate these benefits with a real-world case study: the AI-powered inspection of an additively manufactured manifold.

Join us to discover how deep learning and advanced analytics streamline quality control, improve efficiency, and ensure superior defect detection in industrial AM inspection.

Presentation language: EN

Speakers (1)