Demonstration of novel fiber-coupled phosphor thermometry in a laser powder bed fusion process

AlSi10Mg powder was mixed with the thermographic phosphor, and the measured temperature profiles are compared to the profiles detected by pyrometry and thermocouples. The methods efficacy and potentials, as well as the present uncertainties are discussed.

Bookmark

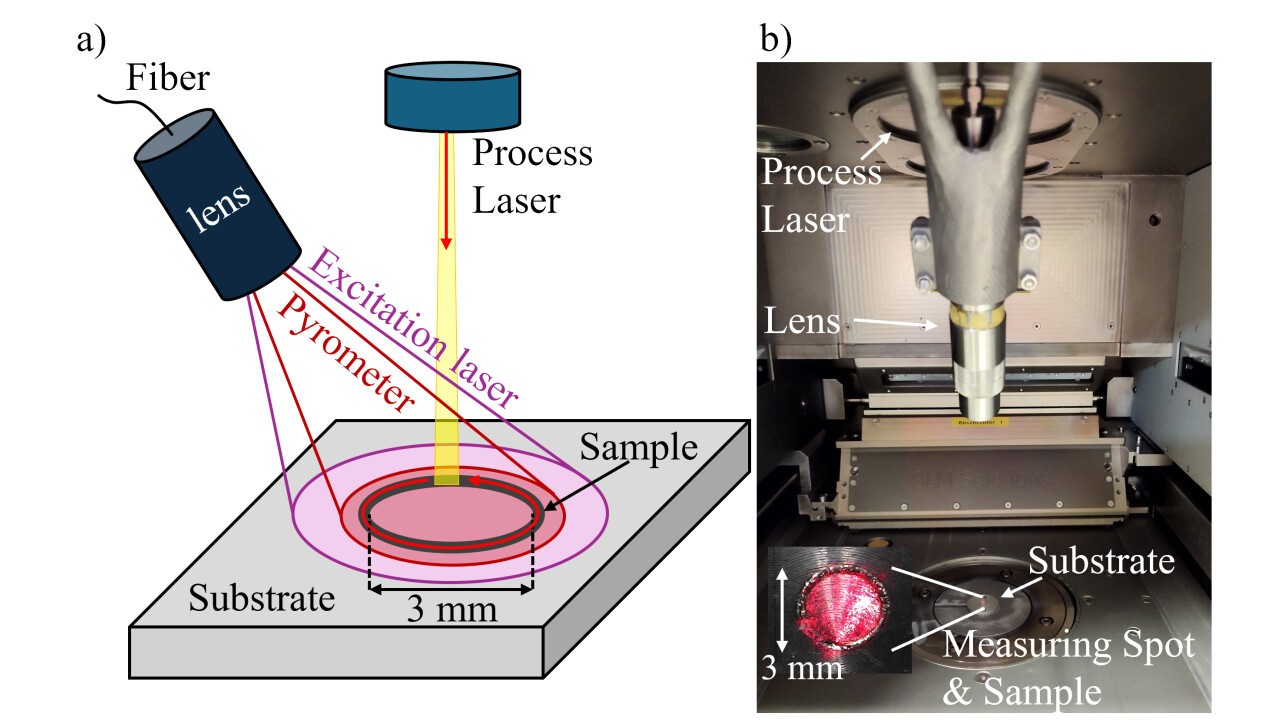

This work introduces a novel in-situ approach to analyze the thermal history during the laser-based powder bed fusion of metals, utilizing phosphor thermometry. AlSi10Mg powder was mixed with the thermographic phosphor MFG:Mn, serving as a temperature marker. After calibration, this powder blend was employed in the PBF-LB/M process, where it was excited in-situ by the third harmonic of an external pulsed Nd:YAG laser. The decay of the thermographic phosphor’s luminescence lifetime showed a notable decrease, indicating temperature increases associated with the process. These findings were compared to in-situ pyrometer and thermocouple measurements, demonstrating the method’s efficacy. While the study discusses the current challenges and uncertainties associated with in-situ phosphor thermometry, it ultimately presents the methods benefits as a promising complement to conventional pyrometric and tactile measurement techniques for in-situ process monitoring. This novel method enhances the thermal measurement range, particularly towards lower temperatures, facilitating improved monitoring of thermal cycling in additive manufacturing processes.

Presentation language: EN

Speakers (1)