Hybrid Additive Manufacturing of Tool Components in a Multi-Material Design

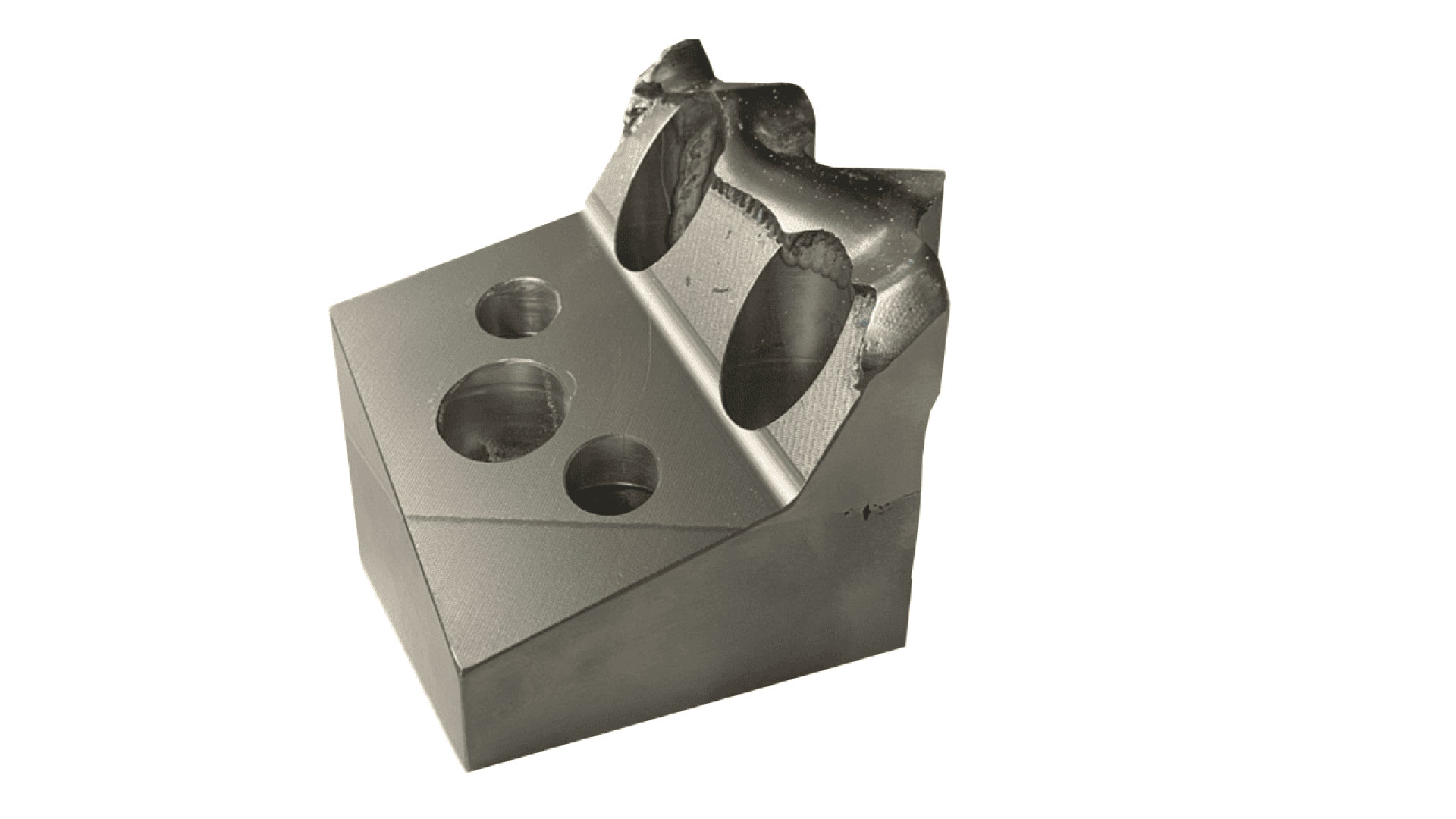

This presentation will demonstrate ways of realising the potential of hybrid additive manufacturing for series production. By using the example of a tool component, methods to prevent the formation of cracks in the component will be presented.

In the automotive industry, the growing demand for customised products is leading to shorter development cycles for car models. To ensure competitiveness, car manufacturers are focussing on new and innovative manufacturing processes. In this context, additive manufacturing processes in toolmaking offer great potential, as individual tool components can be produced hybrid-additively and cost-efficiently by using the directed energy deposition process. However, there are many challenges for using the technology in series production. For example, production guidelines are required to ensure process reliability and avoid welding defects. In addition, a simulation of the welding process enables the prediction of component areas where critical deformations and stresses occur. Another aspect is the economic analysis of the hybrid additive manufacturing approach to identify potential applications and specify economic limitations. This presentation will demonstrate ways of realising the potential of hybrid additive manufacturing for series production. By using the example of a tool component, methods to prevent the formation of cracks in the component will be presented. Furthermore, the development of a simulation model is described, which also offers approaches for the reliable production of tool components. Finally, different hybrid additive manufacturing strategies are shown, which enable a stress-optimised production of the tool component.

Presentation language: GER

Speakers (1)