Robotics industrialized Additive Manufacturing - from industrial 3D-printing to sorting

The synergy of robotics with digital path planning, process control and digital monitoring opens up completely new applications for large-format, extrusion-based 3D printing, increasing production rates while reducing material waste.

Bookmark

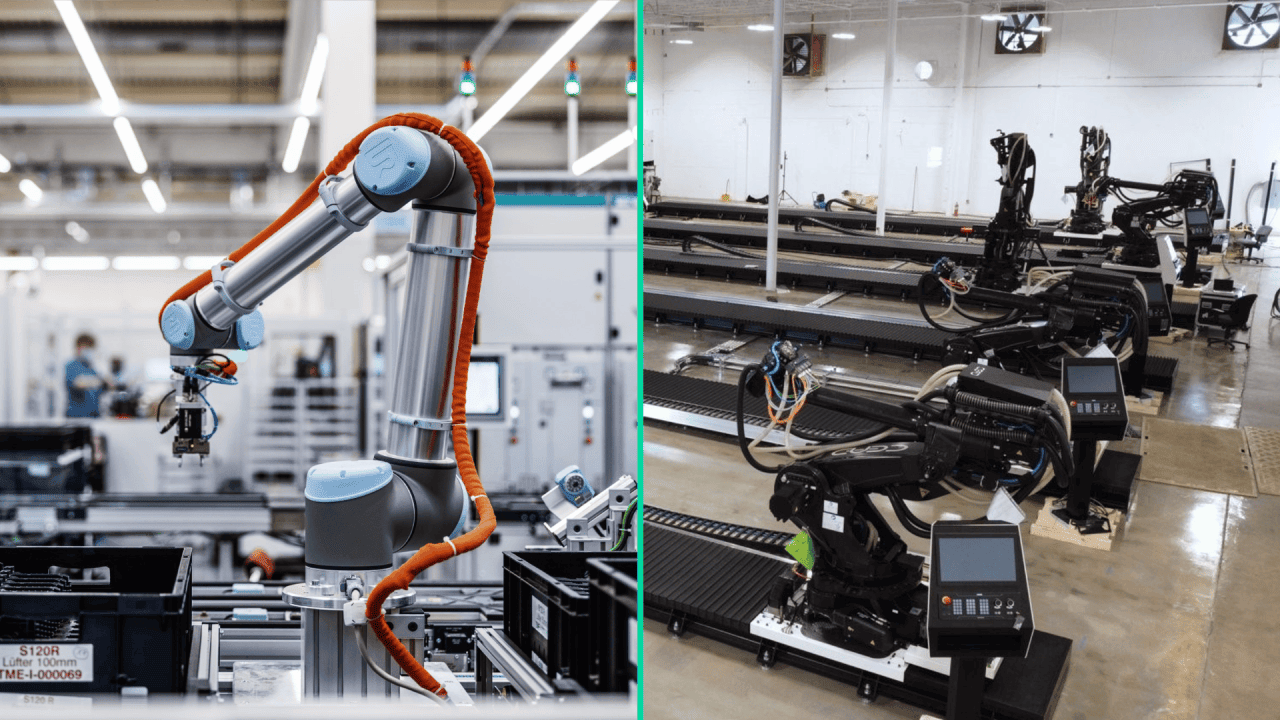

The presentation examines how robotics is advancing the industrialization of additive manufacturing in the printing process itself, as well as in subsequent processes. Robots are increasingly used in large-scale AM production to enhance efficiency and reduce waste, illustrated by the production of 3D-printed furniture by the company Haddy.

Virtual printing simulations allow the extrusion process to be pre-simulated with photorealistic images, which are then used as a reference for a target-actual comparison during printing. Based on this, the extrusion rate and path planning can be optimized within an intelligent end-to-end control system.

Furthermore, robots are taking on tasks such as sorting and part recognition and are using AI for path planning already in other manufacturing industries, as demonstrated at the Siemens production facility in Erlangen. Together, AM and robotics are driving a new era of intelligent production, offering industries a competitive edge through increased productivity, reduced costs, and improved sustainability. This presentation highlights the transformative potential of combining these technologies to modernize and optimize manufacturing processes.

Presentation language: GER