3D printing in sports

3D printing in sports enables customized equipment, improves protection and performance, and brings innovative designs directly to the field. From custom shoe insoles to lightweight helmets, the technology opens up entirely new possibilities.

3D printing has developed rapidly in recent years and is now used in many areas, including sports. This technology offers a wide range of possibilities, both for the production of sports equipment and for individual adaptation and improvement of performance. Thanks to 3D printing, equipment such as shoes, helmets and protectors can be manufactured to fit perfectly and according to the specific requirements of each athlete. This not only leads to better performance, but also to greater safety and increased comfort during training and competition. Production processes also benefit considerably from this technology, as it enables quick and cost-effective solutions. This enables innovative designs and materials to be used that were previously not feasible. 3D printing is thus changing sport and opening up new perspectives for the future. Whether for professional athletes or recreational athletes - this technology offers exciting possibilities that can have a lasting impact on and improve sport. The rapid.tech 3D trade fair offers an ideal platform to come into direct contact with experts in this field in order to learn about innovative applications and the latest developments in 3D printing in sports.

Applications of 3D printing in sports: Various sports presented

3D printing in Football

One outstanding example is the production of football boots that are individually adapted to the shape of the player's foot and running style. These adapted shoes offer optimal comfort and excellent traction, which can significantly improve performance on the pitch.

Shin guards are another example of the use of 3D printing in football. These important protective equipment can be precisely and ergonomically designed to offer players maximum protection without restricting their freedom of movement. Lightweight and robust materials ensure additional comfort and safety during the game. Goalkeeper gloves also benefit from the possibilities of 3D printing. Gloves that are made specifically for the goalkeeper's hands significantly improve grip and ball control. Individual adjustments for flexibility and cushioning help ensure that the gloves function optimally and meet the demands of the game. Training equipment such as hurdles, marker cones and tactical game pieces can also be manufactured precisely and durably using 3D printing. These devices can be individually adapted to the training methods and needs of the team, resulting in more effective training sessions. 3D printing also plays an important role in the medical care of football players. Orthoses and rehabilitation aids can be produced quickly and efficiently to provide optimal support to injured players during their recovery. These personalized aids help speed up the healing process and facilitate your return to the field.

In addition, 3D printing allows the production of special insoles that are tailored to the shape of the player's foot and running technique. These insoles offer better support and cushioning, resulting in reduced fatigue and improved performance.

3D printing in winter sports

3D printing is bringing about numerous innovations and solutions in winter sports that improve performance and the experience on the slopes.

One outstanding example is the production of ski boots. Using precise 3D scans, ski boots can be individually adapted to the shape of the athlete's foot, resulting in better grip and more comfort. This ensures optimal power transmission and control when skiing.

3D printing also offers new possibilities for skis and snowboards. Special structures and materials can be used to reduce weight and increase flexibility. This enables improved maneuverability and stability in different snow conditions. Protective equipment such as helmets and protectors also benefit from 3D printing technology. These pieces of equipment can be designed to fit perfectly and offer maximum protection without restricting freedom of movement. Ergonomic designs and special ventilation systems also provide additional comfort. In ice hockey, 3D printing enables the production of customized sticks and skates. These can be precisely adapted to the player’s playing style and physical needs, which significantly improves performance and the feel of the game. In the same way, 3D printing can be used to optimally produce the game ball, i.e. the puck.

In addition, 3D printing is used to produce innovative training equipment and aids. Individually designed hurdles and markings can be tailored specifically to the training methods of winter sports enthusiasts, resulting in more efficient and effective training sessions.

3D printing in athletics

With optimally fitted running shoes, 3D printing in athletics can help athletes achieve their best performances. The running shoes can be individually adapted to the shape of the athlete’s foot and running style, resulting in an improved fit and increased comfort. Special sole structures and materials enable optimal cushioning and energy transfer, which increases running efficiency. 3D printing also plays an important role in spikes for sprint and middle-distance runners. These spikes can be precisely adapted to the athlete’s needs to maximize traction and stability on the track. Individual adjustments to the number and placement of the spikes ensure optimal performance on different distances and conditions. In the area of throwing disciplines such as shot put, discus and javelin throwing, 3D printing enables the production of personalized grips and gloves. These can be precisely tailored to the athlete’s hand size and grip technique, ensuring better control and power transfer when throwing.

Pole vault poles can also be customized using 3D printing. These poles can be precisely tailored to the needs of the jumper in terms of flexibility and weight, improving jump height and stability in the air. Training equipment and aids also benefit from 3D printing technology. Hurdles, starting blocks and marker cones can be customized and produced to meet the specific needs of the training. These devices contribute to more effective and efficient training sessions.

3D printing in tennis

Tennis rackets are of immense importance for tennis. 3D printing allows them to be manufactured precisely to the needs of the player, with the racket head, frame and handle being adapted exactly to the playing style and preferences. This enables perfect balance and control, which significantly increases the power and precision of the shot.

3D printing is also used in tennis shoes. Custom-fit soles and uppers ensure optimal grip and comfort on the court. The shoes can be specifically tailored to the shape of the player’s foot and movement patterns, improving performance and endurance. Grips and grip tapes are other areas where 3D printing is of great benefit. Players can benefit from grips that are precisely tailored to their hand size and grip technique. This leads to better grip and reduced fatigue during long matches. Furthermore, tennis balls can be optimized using 3D printing. The structure and material of the balls can be customized to provide consistent bounce and durability. This results in more consistent and predictable shots, which raises the level of play. 3D printing also offers innovative solutions in the area of protective equipment. Custom-fit pads and orthotics ensure a better fit and increased protection, reducing the risk of injury and increasing comfort.

3D printing in water sports

From surfboards and kayaks to paddles and sailboat components, the possibilities of this technology are endless and significantly improve performance and the experience on the water. By using 3D printing, surfboards can be manufactured with individual designs and structural adjustments that are perfectly tailored to the needs of surfers. These exclusive boards offer optimal stability and maneuverability on the waves.

3D printing also plays a significant role in kayaking and canoeing. Kayaks and canoes can be printed from lightweight, robust materials that improve handling and speed in the water. Individual adjustments to the shape and structure of the boat ensure optimal performance and comfort. Paddles are another example of the use of 3D printing in water sports. These can be precisely adapted to the athlete's body size and paddling technique, resulting in better power transmission and efficiency when paddling. Ergonomic handles and special blade shapes can be individually designed to meet the requirements of different water sports.

There are also applications for 3D printing in the field of sailing. Sailboats and their components, such as rudders, foils and fittings, can be produced precisely and efficiently. These individual parts improve the aerodynamics and hydrodynamics of the boat, resulting in better speed and maneuverability. In addition, 3D printing enables the production of swimming goggles and diving masks. These pieces of equipment can be perfectly adapted to the shape of the face, ensuring a better fit and increased comfort.

3D printing in equestrian sports

3D printing in equestrian sports can be used to produce saddles tailored to the individual. Precise 3D scans allow saddles to be perfectly adapted to the shape of the horse's back and the rider's seating position. These custom-made saddles ensure optimal weight distribution and increase comfort for both.

Stirrups can also be customized using 3D printing technologies. These stirrups are not only lightweight and durable, but also ergonomically designed to optimize the position of the feet and increase safety. The adjustment options ensure better control and balance while riding. In the field of horse health, 3D printing also offers innovative solutions. Hoof boots can be precisely adapted to the horse's hoof shape, resulting in better protection and support for hoof health. These hoof boots are particularly useful for horses with special orthopedic needs or injuries. Helmets and other protective equipment for riders also benefit from 3D printing. Helmets can be individually adapted to the shape of the head, resulting in a better fit and greater protection. Ergonomic designs and special materials provide additional comfort and safety.

In addition, 3D printing enables the production of training aids and accessories that are precisely tailored to the needs of riders and horses. For example, bridles and bits can be designed to fit perfectly in the horse's mouth and increase comfort.

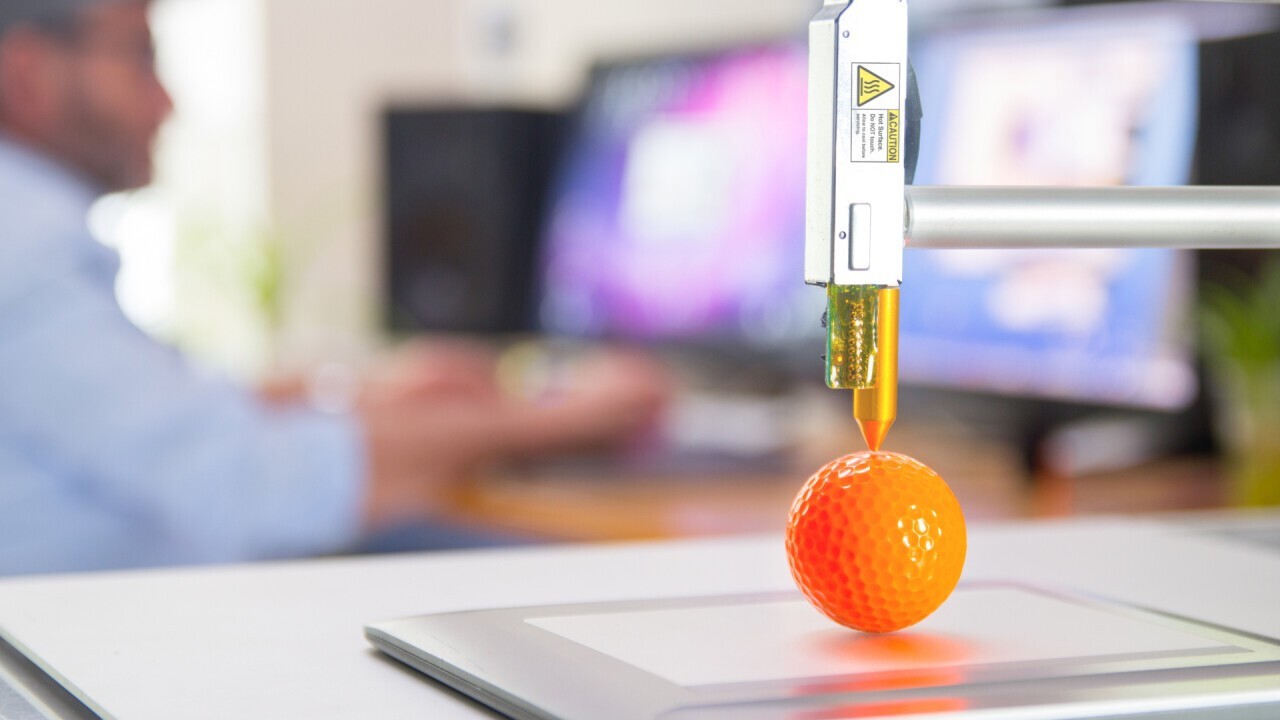

3D printing in golf

3D printing brings exciting innovations and special solutions to golf that take the game to a new level. A notable example is the production of specific golf clubs. By using 3D printing, club heads and shafts can be manufactured precisely according to the needs of the golfer. These clubs improve balance, weight and hitting precision, which leads to better playing performance.

Golf club grips also benefit from 3D printing technology. These can be ergonomically designed and precisely adapted to the player's hand size and grip technique. This ensures a better grip and optimal power transfer with each swing. The grips can also be provided with special textures and patterns that improve grip in different weather conditions. Golf club heads, especially putters, can be customized using 3D printing to optimize the hitting surfaces and weight distribution. This enables more precise control and increases the chances of successful putts. Golfers can personalize their club heads with unique designs and structures that match their playing style. Custom-designed training equipment such as swing trainers and putting practice aids can be specifically tailored to the golfer's needs and goals using 3D printing. The aids contribute to more effective training sessions and faster skill improvement. Golf balls also benefit from the possibilities of 3D printing. By making precise adjustments to the structure and weight of the ball, the flight characteristics and stability in the game can be optimized. This leads to more consistent and predictable shots.

3D printing for hiking, mountaineering and climbing

In hiking, customized hiking boots printed using 3D printing are a real asset for all hikers. By using 3D printing, the soles and upper material can be tailored precisely to the shape of the foot and the specific needs of the wearer. This ensures optimal comfort and better grip on different types of terrain.

In the field of mountaineering equipment, 3D printing enables the production of specific crampons and ice axes. These tools can be precisely adapted to the needs of the mountaineer and the conditions of the route, resulting in better performance and safety in extreme environments. The combination of light weight and high stability makes these pieces of equipment particularly valuable. Climbing equipment also benefits from 3D printing technology. Climbing holds and carabiners can be made from light but robust materials and designed in ergonomic designs. These customized pieces of equipment improve safety and efficiency when climbing. Carabiners can also be given special mechanisms and shapes that increase handling and load-bearing capacity.

In addition, backpacks and carrying systems can be optimized using 3D printing. Individually designed back pads and straps ensure better weight distribution and increased comfort, which is particularly important on long hikes and difficult climbing tours. These adjustments help to reduce the strain on the body and increase endurance.

Furthermore, 3D printing enables the production of individual protective equipment such as helmets and knee pads. These can be ergonomically designed and adjusted precisely to the wearer's body measurements, resulting in a better fit and increased protection. Special ventilation systems and padding also provide additional comfort and safety.

3D printing in martial arts

By using 3D printing, mouthguards can be precisely molded to the fighter's dental structure, resulting in an optimal fit and maximum protection. These custom-made mouthguards not only offer greater comfort, but also improved breathing ability and communication during the fight.

3D printing also shows its strengths in protective equipment such as head guards and gloves. Head guards can be designed to perfectly fit the shape of the athlete's head, offering better protection and comfort. The use of lightweight and durable materials such as TPU and nylon provides additional protection and freedom of movement. In the case of gloves, padding and flexibility can be customized to maximize impact power while protecting the wrists.

Shin guards and foot protectors are other examples of the use of 3D printing in martial arts. These pieces of equipment can be precisely shaped to the fighter's anatomy, resulting in a better fit and protection. Materials such as polypropylene and EVA are often used to create lightweight and robust protective equipment that can withstand the rigors of training and competition. 3D printing also offers innovative possibilities in the area of training equipment. Punching bags and striking pads can be provided with special structures and materials that improve durability and impact absorption. Custom-designed training aids can be specifically tailored to the fighter's needs and techniques, resulting in more effective training sessions.

The different materials and filaments in 3D printing for sports materials

In football, thermoplastic polyurethanes (TPU) are often used to make custom-fitted football boots and shin guards. TPU offers excellent elasticity and durability, increasing comfort and safety on the pitch. Shin guards made of nylon and polypropylene offer additional protection with minimal weight.

Carbon fibre reinforced plastics (CFRP) are used in winter sports. These materials are extremely light and robust, ideal for the production of ski boots, skis and snowboards. The use of CFRP enables the production of equipment that can withstand the stresses of the slopes while improving maneuverability. Water sports also benefit from 3D printing. Kayaks, paddles and surfboards made from composite materials such as fibreglass and carbon fibre are lighter and more stable. Nylon and polyethylene are used to make swimming goggles and diving masks, which offer a perfect fit and high durability. In athletics, 3D printing enables the production of cut-to-size spikes and running shoes. Thermoplastic elastomers (TPE) and TPU ensure optimal cushioning and flexibility. PEEK (polyetheretherketone) is often used for orthotics and medical devices that assist athletes in rehabilitation.

In equestrian sports, saddles and stirrups are made of TPU and nylon. These materials provide the necessary strength and flexibility to ensure both comfort and safety. Polyurethane hoof boots provide additional protection and support for the horse's hooves. Golf uses 3D printing to produce custom-fit golf clubs and grips. Aluminum and CFRP are used for the club heads, while TPU and silicone provide ergonomic handles that allow for better control and hitting precision. In hiking, mountaineering and climbing, 3D printing plays an important role in the production of equipment such as climbing holds, carabiners and backpacks. Aluminum and titanium are valued for their lightness and strength, while TPU and nylon are used for ergonomic handles and padded carrying systems. The variety of materials used in 3D printing is also evident in tennis. Tennis rackets can be made of CFRP and aluminum to achieve the perfect balance between weight and stability. Handles made of TPE and TPU offer players better grip and comfort, improving performance on the court.

In 3D printing for martial arts, materials such as thermoplastic polyurethane (TPU) and nylon are often used to produce flexible, robust and lightweight protective equipment. These materials offer optimal protection and high wearing comfort, which is particularly advantageous for individually fitted mouth guards, head guards and gloves.

Whether in football, winter sports, water sports, athletics, equestrian sports, golf, hiking, mountaineering, climbing, tennis or martial arts - the tailor-made equipment made of materials such as TPU, nylon, CFRP and PEEK is revolutionizing the world of sport and setting new standards for performance and safety.

Your contact person