Press release rapid.tech 3D 2024

3D printing: catalyst for the energy and transport transitions

The potential of additive manufacturing for energy and hydrogen technologies will be discussed at the Innovations in Additive Manufacturing forum on 16 May 2024 at Rapid.Tech 3D

-

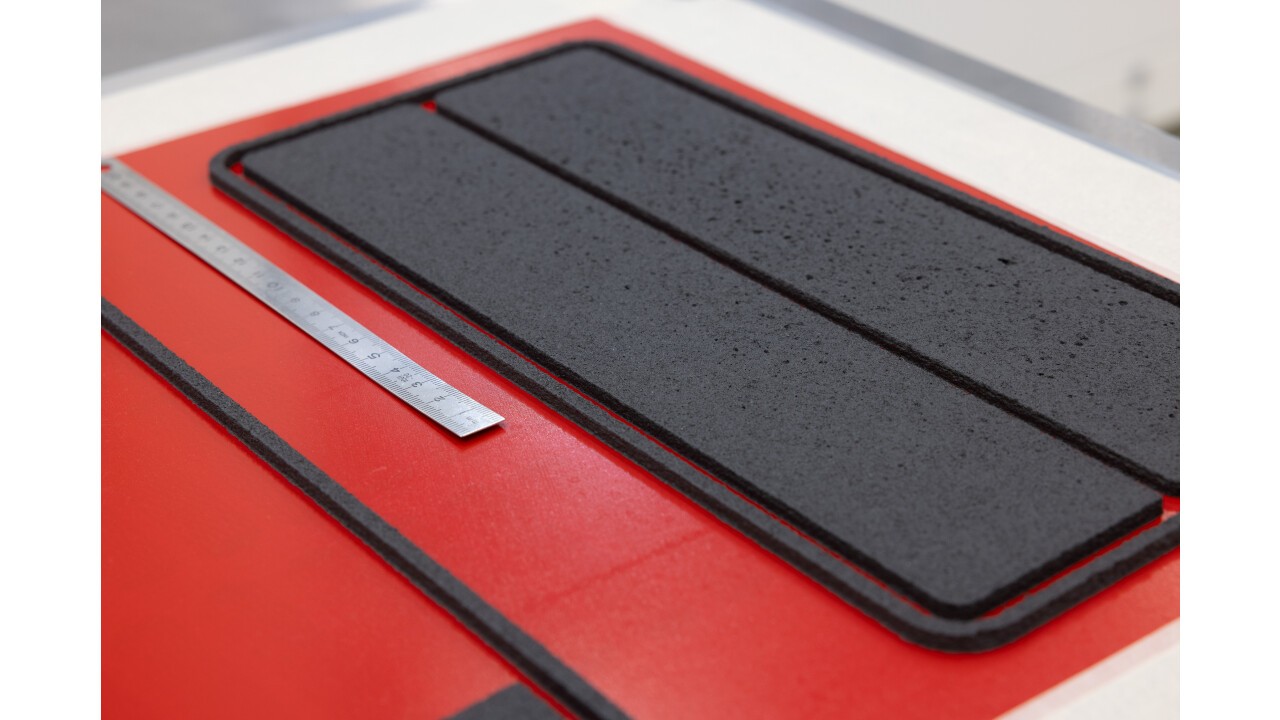

Bipolarplatte_copyright_Lars_Wiedemann

“We will cover everything from fuel cells and gas turbines to fusion reactors and, in addition to industrial applications, show how school projects on 3D printing are sparking interest in these topics,” says Dr Eric Klemp, Head of Hydrogen and Additive Manufacturing at Whitecell Eisenhuth GmbH & Co. KG, speaking about the content of the forum. A member of the Rapid.Tech 3D advisory board, Dr Klemp is organising the session on energy and hydrogen.

Bringing the “green” kilometre to the market

Hydrogen-powered fuel cell vehicles are becoming increasingly important for clean transport solutions; and an essential component of fuel cell power stacks is bipolar plates. Whitecell already has extensive experience with this technology. Among other things, the company uses 3D printing to produce graphite bipolar plates. These panels are manufactured quickly and individually using a special screen printing process. Dr Martin Hintermann, CEO of Switzerland’s Whitecell Power AG, will present processes and applications that are helping bring the “green” kilometre to the market.

Getting started with fuel cell production – for everyone

The Duisburg Centre for Fuel Cell Technology’s Open Fuel Cell project provides an introduction to 3D printing and energy technologies for everyone. Livia C. Wiedau, Head of the 3D Fab Lab at the University of Duisburg-Essen, will report on using practical examples to teach students about additive and subtractive manufacturing. Learners are given instructions and equipment to enable them to produce simple fuel cells and generate their own electricity from hydrogen. The open source blueprint can be used by anyone who is interested.

Additive manufacturing: the key to hydrogen gas turbines

The presentation by Dr Sebastian Piegert, Head of Department at Siemens Energy Gas Services, will focus on large-scale generation OF clean power. Siemens Energy is aiming to run its entire gas turbine portfolio with 100 percent hydrogen by 2030. This requires comprehensive restructuring of their combustion systems. Key to the systems' reconfiguration is additive laser melting, which enables the creation of complex cooling functions and fuel gauges that cannot be delivered with conventional production techniques.

Printing dense tungsten with electron beam powder bed fusion

Fusion energy is seen as a potential solution to the world’s energy problems. However, the fusion takes place under high temperatures and emits extreme levels of radiation. This places significant demands on the materials used in fusion reactors, especially components on the plasma side. Pure tungsten is currently considered the most suitable material for this purpose. However, the metal is difficult to process, and this has thus far limited its potential applications and the production methods that can be used. Freemelt has succeeded in printing dense tungsten parts at high speed using electron beam powder bed fusion. Dr Ulric Ljungblad, CIO of the Swedish company, will present the process.

Further topics at the Innovations in Additive Manufacturing trade forum

In addition to energy and hydrogen, the Innovations in Additive Manufacturing forum is offering two further sessions. There will be an overview of 3D-printed electronics with examples of application on 16 May. The previous day (15 May), speakers from Rheinmetall and other companies will talk about the importance of additive manufacturing for the production and maintenance of defence technology.

Specialist conference with eight industry and science forums

Alongside the Innovations in Additive Manufacturing trade forum, other forums at the Rapid.Tech 3D specialist conference will provide insights into the latest developments and applications in additive manufacturing. On the first day of the event (14 May 2024), the AM4industry format organised by the Additive Manufacturing Working Group of the German mechanical and plant engineering association VDMA will welcome visitors for the first time. The established Aerospace forum is also set to take place that day, as is the Additive Manufacturing Science forum, which will continue into day two (15 May 2024). On day two, the Chemical and Process Engineering forum, presented by DECHEMA, and the Innovations in Additive Manufacturing forum will also run, alongside the Software, AI and Design forum. The Mobility and Additive Manufacturing Science by Fraunhofer forums will take place on the final day (16 May 2024).

About Rapid.Tech 3D:

In just two decades, Rapid.Tech 3D – with the specialist conference as its centrepiece – has become one of Central Europe’s leading additive manufacturing trade events. This year’s event will be held from 14 to 16 May at Messe Erfurt.

More at: www.rapidtech-3d.de/en

About Messe Erfurt GmbH:

Central Germany’s largest trade show and conference venue, Messe Erfurt has established itself as a forum for businesses, scientists, doctors, trade unions and many other institutions. Every year, it hosts over 220 events, conventions, conferences, trade fairs, exhibitions, corporate events and concerts, attracting over 650,000 visitors.

More at: www.messe-erfurt.de/en/

Trade Media Contact

Ina Reichel

- Freelance Journalist -

Mob: +49 172 602 94 78

inareichel@ma-reichel.de