Metal Additive Manufacturing – Faster Innovation for the Bicycle Industry

Möve recognized the constraints of the industry, such as high tool costs for high standardized bicycles. With Eplus3D's help, they building the first titanium bicycle frame in monocoque look with full battery integration worldwide made of 3D printed titanium lugs

Bookmark

The integration of innovative technologies from Asia to Central Europe, while at the same time maintaining cost efficiency, has been a major challenge in the development process.

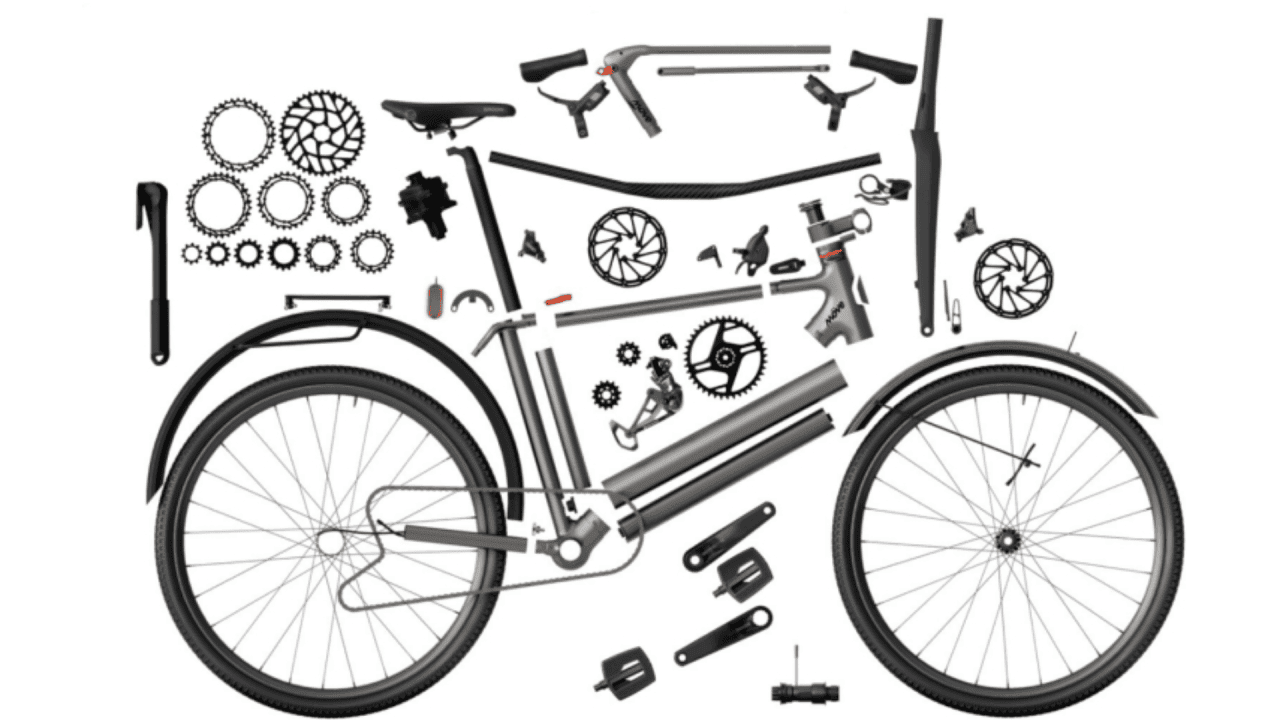

After a long history, bicycle manufacturer Möve developed the principle of using Additive Manufacturing (AM) to produce the connectors between the tubes of a bike frame. After evaluating potential partners in order to succeed in this technological breakthrough, Möve identified a need for an excellent collaboration and expertise that would deliver the cost efficiency, design and performance in line with one single manufacturer.

Eplus3D's team focused on optimizing the cost structure for the production of connectors and ensuring the feasibility of scaling the project into series production. By implementing this approach and supporting Möve in the never made before titanium tubes for the frame, the project was timely accelerated by a minimum of four months, resulting in the creation of a new and distinctive e-bike frame that preserved the original intended monocoque design.

This project illustrates the potential for the bicycle industry through the use of Metal 3D printing and a valuable combination of engineering work from all parties. Recognition of the challenges is critical to mobility industries, prompting them to rethink and redesign how parts' production are made, delivering a high quality and durable product that enhances the final user experience.