Press release rapid.tech 3D 2024

From the 3D printer to a safe lift-off

Aerospace forum on opening day of Rapid.Tech 3D to focus on digitalisation of the AM process chain. Well-known aircraft manufacturers and aviation groups, up-and-coming start-ups such as innovative research institutes will all be taking part.

-

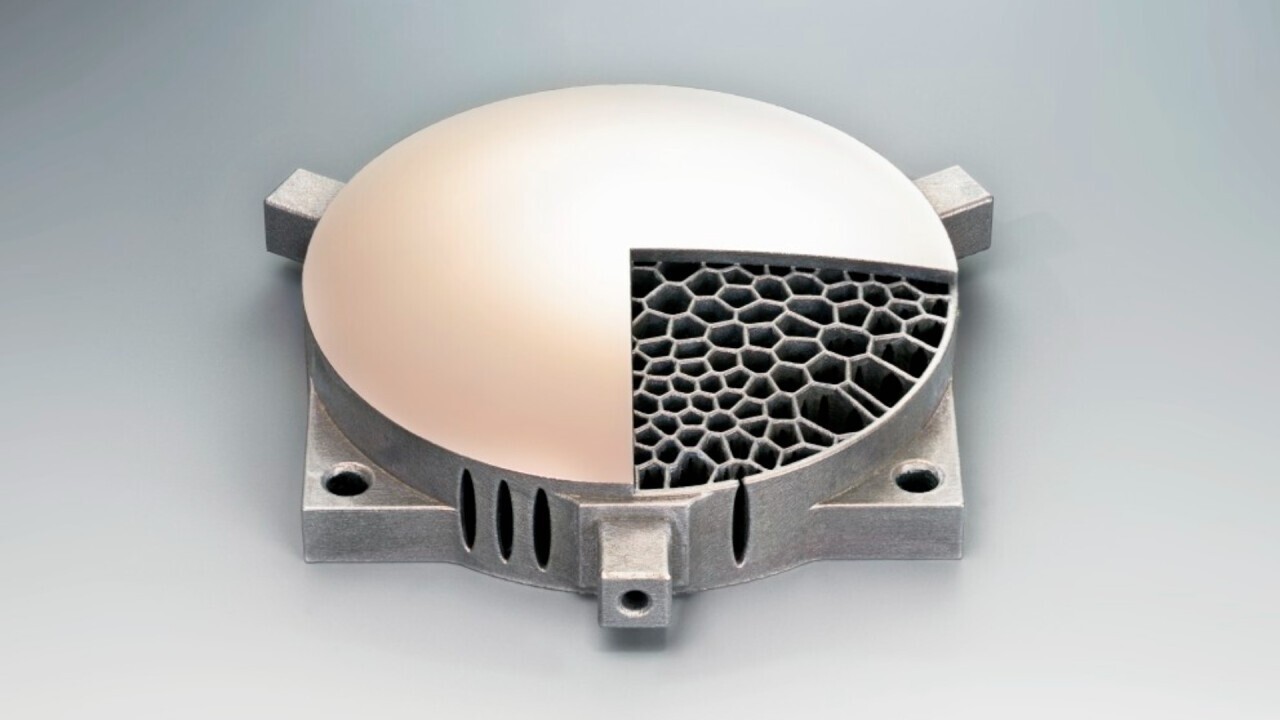

Fraunhofer IOF_Additively manufactured metal mirror with internal light-weight structure

Digitalisation: a key lever

“The forum will highlight the progress that additive manufacturing has made in the aerospace industry, as well as the challenges that remain. It is now possible to additively manufacture ever larger components in an increasing variety of materials. Digitalisation is a key lever for achieving even greater precision, speed and efficiency. This applies to every link in the chain. There is still a lot of potential to be tapped here, especially in the digital quality control and certification of AM parts. This helps to make the entire process sustainable,” says Stephan Eelman, Director Research & Cooperation at Boeing Global Services, who as a member of the Rapid.Tech 3D advisory board and is overseeing the content of the forum.

Integrated approach to digital quality control

AM applications for aircraft cabins, digital quality control of AM components, near-net-shape production of parts using the WAAM process and automated engine repairs are the main focus of the presentations on the aviation sector. Dr Aenne Köster, Head of Additive Engineering and Manufacturing at Lufthansa Technik, will be speaking on the development, approval and potential of AM components in aircraft cabins. Lufthansa Technik uses additive manufacturing for both the design and redesign of cabin components. AM is particularly helpful for the design of VIP aircraft components that are tailored to customer requirements. And the redesign process is not just about re-creating parts, it is also about improving how they work.

The presentation by Dr Jazib Hassan, Lead AM Engineer at Boeing Research Technology Europe, will focus on how Boeing is moving AM towards digital quality control and sustainability. Digital quality control of AM parts requires an integrated approach that utilises digital technologies, simulations and data-driven insights to ensure the reliability, safety and performance of AM components. Dr Hassan will focus on simulation and modelling, process monitoring and control, quality assurance and inspection, and life cycle management of metal additive parts.

Larger components and faster repairs with AM

Energy-efficient additive technologies that also have material efficiency are becoming increasingly important on the road to sustainable aviation. Sascha Berbalk from Heggemann AG will present the WAAM process, which the supplier has enhanced and industrialised in order to produce larger, near-net-shape components using less material. Digitalisation of the entire process chain, from 3D model to digital certificate, plays a key role in ensuring reproducible, aviation-grade quality.

In his session, Simon Feicks from AdditiveStream will demonstrate that a digitalised, automated AM process chain helps speed up engine component repairs. The start-up focuses on maintenance services using processes such as laser powder bed fusion (LPBF) and directed energy deposition (DED) and has developed hardware and software solutions in this sector.

AM research for space travel

Juri Munk from the German Aerospace Center (DLR) and Dr Lukas Werling from the DLR spin-off InSpacePropulsion Technologies ISPTech will provide insights into DLR research in the field of laser powder bed fusion and its application in propulsion products for space travel. Among other things, they will be presenting a digital tool that visualises process monitoring data three-dimensionally and maps it onto the CAD of the part. These and other developments are intended to pave the way for the commercialisation of environmentally friendly propulsion technologies, for example for satellites.

Dr Nils Heidler from the Fraunhofer Institute for Applied Optics and Precision Engineering IOF will highlight the AM potential for metal mirrors and optical components for use in space. He will emphasise the need for an extremely precise and stable overall production chain, including a number of post-processing steps to eliminate defects, impurities or surface roughness.

Specialist conference with eight industry and science forums

Alongside the Aerospace trade forum, other forums at the Rapid.Tech 3D specialist conference will provide insights into the latest AM developments and applications. On the first day of the event (14 May 2024), the AM4industry format organised by the Additive Manufacturing Working Group of the German mechanical and plant engineering association (VDMA) will welcome visitors for the first time. The AM Science forum will also start that day, continuing into day two (15 May 2024). On day two, the Chemistry and Process Engineering forum – presented by DECHEMA, the Software/AI & Design forum and the Innovations in AM forum will also run, with Innovations in AM continuing on day three (16 May 2024). The Mobility and AM Science by Fraunhofer forums will also take place on this final day.

About Rapid.Tech 3D:

Over the course of two decades, Rapid.Tech 3D – with its centrepiece specialist conference – has become one of Central Europe’s leading AM trade events. This year’s event will be held from 14 to 16 May at Messe Erfurt.

More at: www.rapidtech-3d.de/en

About Messe Erfurt GmbH:

Central Germany’s largest trade show and conference venue, Messe Erfurt has established itself as a forum for businesses, scientists, doctors, trade unions and many other institutions. Every year, it hosts over 220 events, conventions, conferences, trade fairs, exhibitions, corporate events and concerts, attracting over 650,000 visitors.

More at: www.messe-erfurt.de/en/

Trade Media Contact

Ina Reichel

- Freelance Journalist -

Mob: +49 172 602 94 78

inareichel@ma-reichel.de