Novelty rapid.tech 3D 2024

DED-L/W technology, the missing link in metal AM

The DED-L/W technology (Directed Energy Deposition Laser Wire) closes a gap in the quality parts gained from laser melting and WAAM (Wire Arc Additive Manufacturing).

The DED-L/W technology (Directed Energy Deposition Laser Wire) closes a gap in the quality parts gained from laser melting and WAAM (Wire Arc Additive Manufacturing).

FIT AG, a leading expert in the field of additive manufacturing, is expanding its technology portfolio in the field of wire welding with DED-L/W.

FIT has a large, manufacturer-independent machine park with a wide variety of technologies. FIT already has many years of experience and extensive know-how in the field of additive processing of metals. Meltio's DED-L/W technology further differentiates FIT's range of manufacturing solutions, further consolidating the company's position as market leader in this sector.

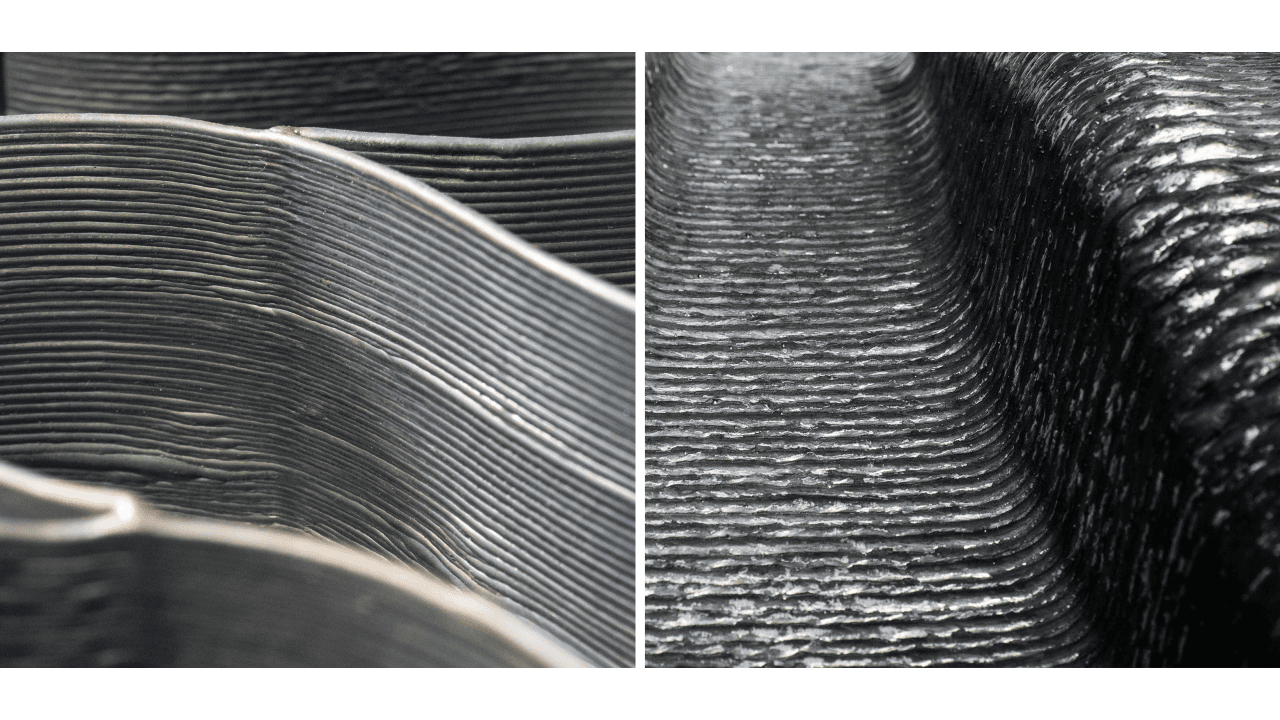

Meltio's DED-L/W technology is characterized by high precision and efficiency and combines laser melting and WAAM, whose properties complement each other in the spectrum of manufacturing technologies. While the powder bed process of laser melting allows fine structures, WAAM is characterized by high build-up rates and a larger component volume. In the performance gap between the advantages of the two processes, DED-L/W represents a smooth transition, with a finer resolution than WAAM and significantly higher build speed and lower costs compared to laser melting.

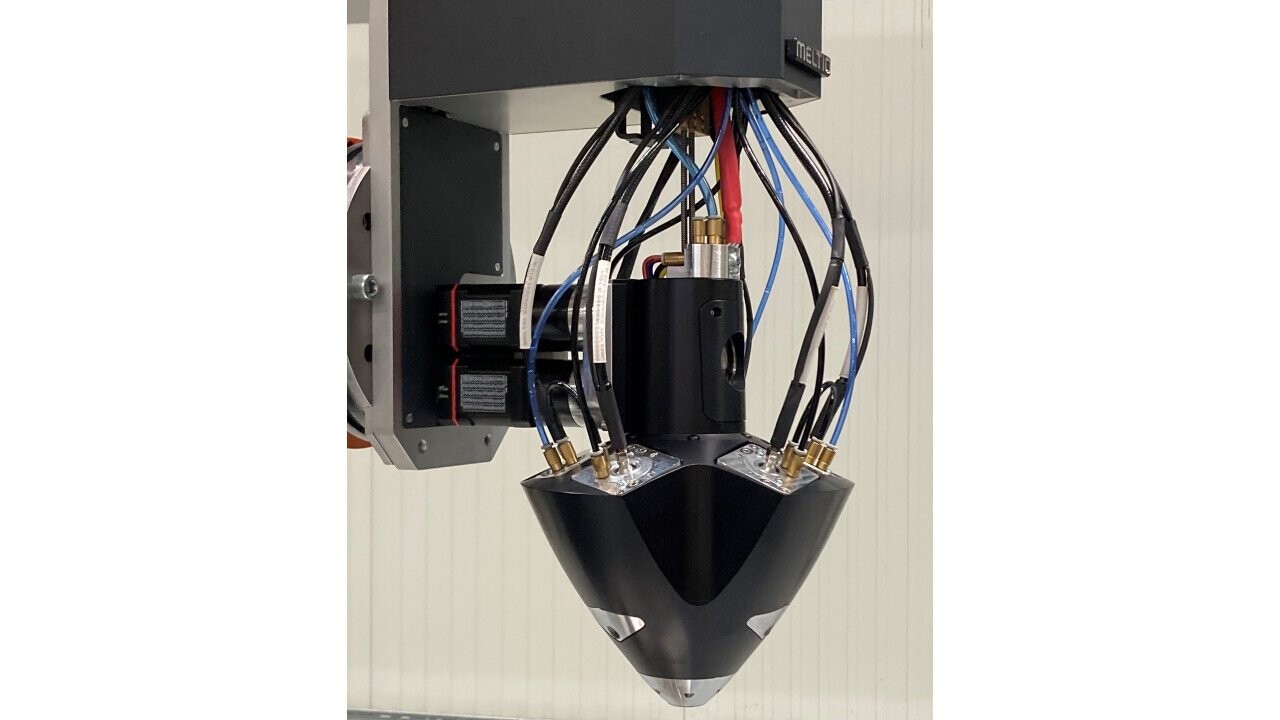

The technology has already been evaluated in advance at FIT using a test system provided by Know-How Wilhelms with convincing results. A major advantage is that the Meltio Engine can be easily coupled with the industrial robots at FIT, so that the FIT experts can also use and further expand the special expertise they have in the area of multi-axis toolpath programming from their experience with WAAM for DED-L/W as well.

Carl Fruth emphasizes the relevance of the new process: "Meltio's DED Laser Wire technology is an ideal extension of metal AM technologies. The rule of thumb is: Meltio is the method of choice wherever WAAM is too coarse and laser melting is too expensive. We look forward to working with our customers to develop a variety of new applications with this technology that meet the highest quality standards."

In addition to its use as the sole manufacturing process, the hybrid manufacturing possibilities are particularly interesting, in which DED-L/W can be used to apply fine wire structures to metal components from other manufacturing processes such as laser melting, WAAM or casting, for example for the repair and reinforcement of components and tools. This makes the new process an interesting option in the area of spare parts supply, for example.