Every company has to face the challenges of increasingly efficient and sustainable manufacturing. DMG MORI supports its customers with Machining Transformation (MX).

The new concept combines the four pillars of Process Integration, Automation, Digital Transformation (DX) and Green Transformation (GX) for modern and sustainable manufacturing. In the series production of the Robo2Go head, DMG MORI uses the full potential of process integration – 3D printing, automated complete machining and digitization – at all levels.

Established processes and tools in machining are constantly evolving, while new technologies, including integrated systems in digital value creation networks, are dynamically gaining influence. With increasing automation in machine tool manufacturing, the further development of robots is gaining in importance. DMG MORI has also continuously optimized its Robo2Go, which is particularly evident in the example of the robot head. This originally consisted of an assembly with 79 conventionally manufactured individual parts. ADDITIVE INTELLIGENCE, a consulting unit of the DMG MORI Academy, has set itself the task of sustainably optimizing processes relating to the manufacture of such complex products – with the far-reaching possibilities of additive manufacturing. In this process optimization, 3D printing is an important basis on the one hand, but only one of several building blocks on the other. Digitization measures, automated handling and the use of innovative processing technologies are essential components of the holistic manufacturing solutions.

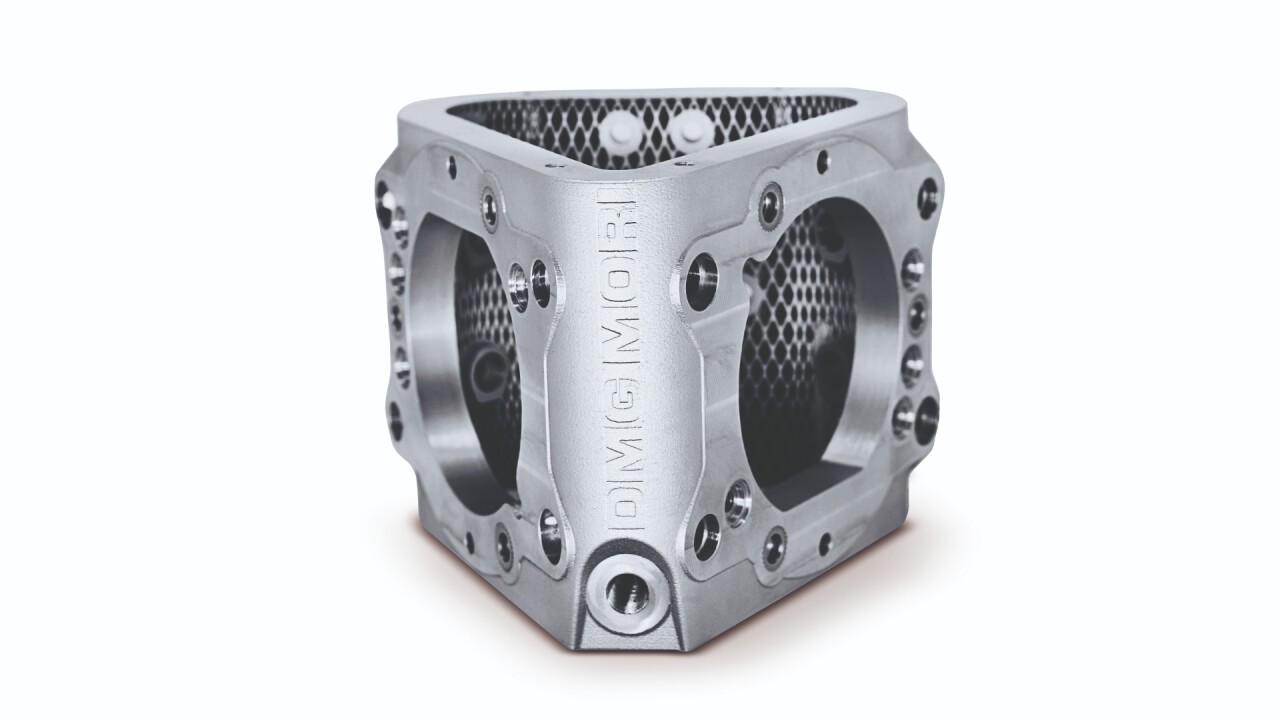

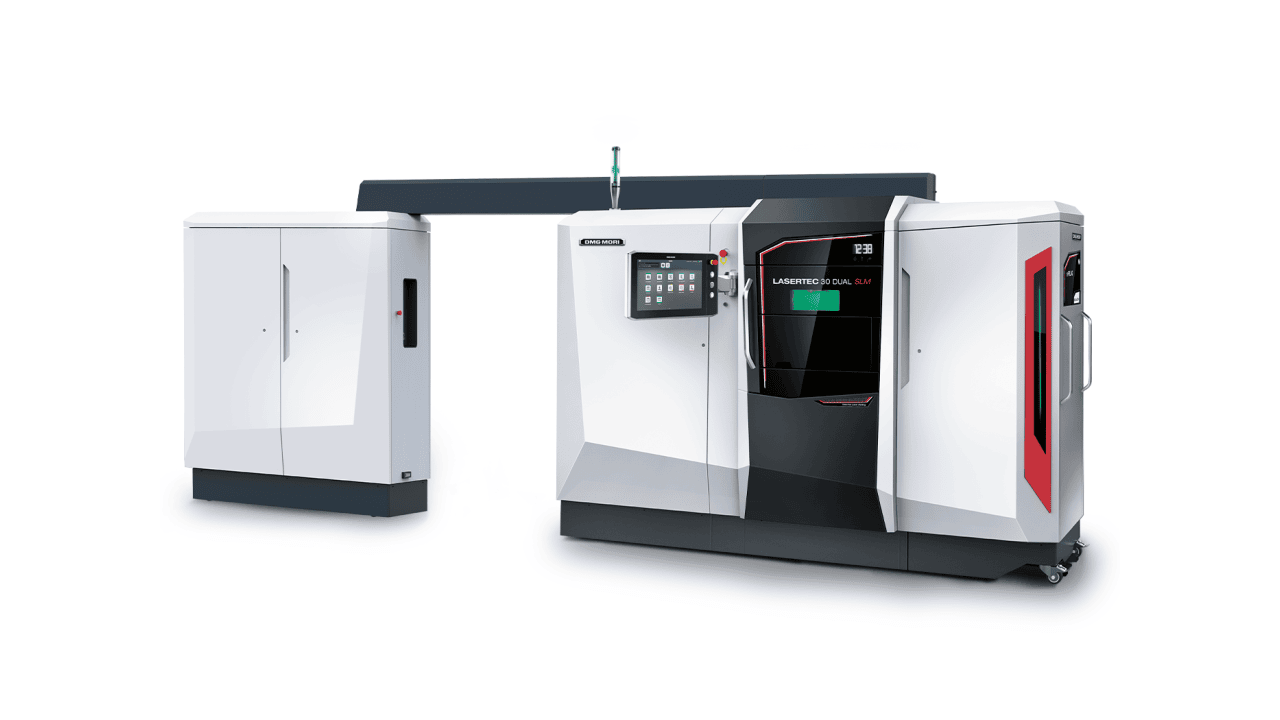

"With the possibilities of additive manufacturing, we can optimize the design of components and completely rethink entire processes," says Dr Rinje Brandis, Head of Consulting Additive Manufacturing, about the major influence of 3D printing of metallic components. By manufacturing the robot head in the powder bed of the LASERTEC 30 DUAL SLM, only less than half of the individual parts are required. "We were able to reduce the weight by 65 percent thanks to a load-oriented component design based on a topology analysis with integrated components." The number of seals was also almost halved thanks to integrated cooling channels, among other things. "What's more, the robot head is compatible with all gripper types." Overall, the new Robo2Go head impresses with a 16-fold increase in positioning accuracy and a significant reduction in assembly work.

Process optimization consistently tested in own development

The new manufacturing approach around the head of the Robo2Go is now ready for series production and is a perfect example of the major trend towards process integration. With a view to the future of machine tool construction, it is the defining topic for DMG MORI – a topic that ADDITIVE INTELLIGENCE has consistently implemented in the case of the robot head, as Dr. Rinje Brandis explains: "Additive manufacturing in the powder bed requires a series of additional process steps until the finished component is produced." The LASERTEC 30 DUAL SLM can build four parts on one build plate. "These must first be freed from the powder, which we do in a Solukon SFM-AT350."

Automated complete machining including in-process measuring

The robot heads are then separated from the plate using wire erosion. "The separated components are then ready for final machining on the 5-axis DMU 40," says Dr. Rinje Brandis, explaining the rest of the process. The 5-axis machining center enables efficient complete machining of the robot head. At the same time, measuring processes can also be integrated into the machining process in order to reduce the work involved in the final quality control. Machining on the DMU 40 is also all about automated complete machining. "The compact machining center is equipped with a Robo2Go. It is the optimum solution for medium batch sizes in the production of the robot head."

Digitization as an essential component of process integration

Digitization also plays a central role throughout the production of the Robo2Go head. This is because the components are given a data matrix code right from the start, which acts as a digital product file. "We use this code to document all production-relevant information relating to the component - from the serial number and specific parameters to all processing steps that have already taken place," says Dr. Rinje Brandis. "The Data Matrix Code enables efficient and transparent order processing, from the customer order to the selection of the right NC programs and quality control."

Intelligent support throughout the entire process

The DMG MORI Messenger, the Performance Monitor and the Condition Analyzer allow efficient monitoring and analysis of machine conditions, which means downtimes can be avoided at an early stage. DMG MORI also relies on digitized processes for servicing and maintenance: With the free online portal my DMG MORI, faults are transmitted quickly and forwarded directly to the right contact person. To ensure uniform standards and consistent quality in assembly as well, ADDITIVE INTELLIGENCE relies on TULIP, another product in DMG MORI's large digitization portfolio. "With the platform, we can create assembly instructions in the form of apps that explain all the necessary steps and set checkpoints so that every robot head is error-free," says Dr. Rinje Brandis, describing the added value.