VDMA AM4industry forum rapid.tech 3D 2024

Additive manufacturing as a resource saving alternative in the manufacturing process of marine gearbox housings

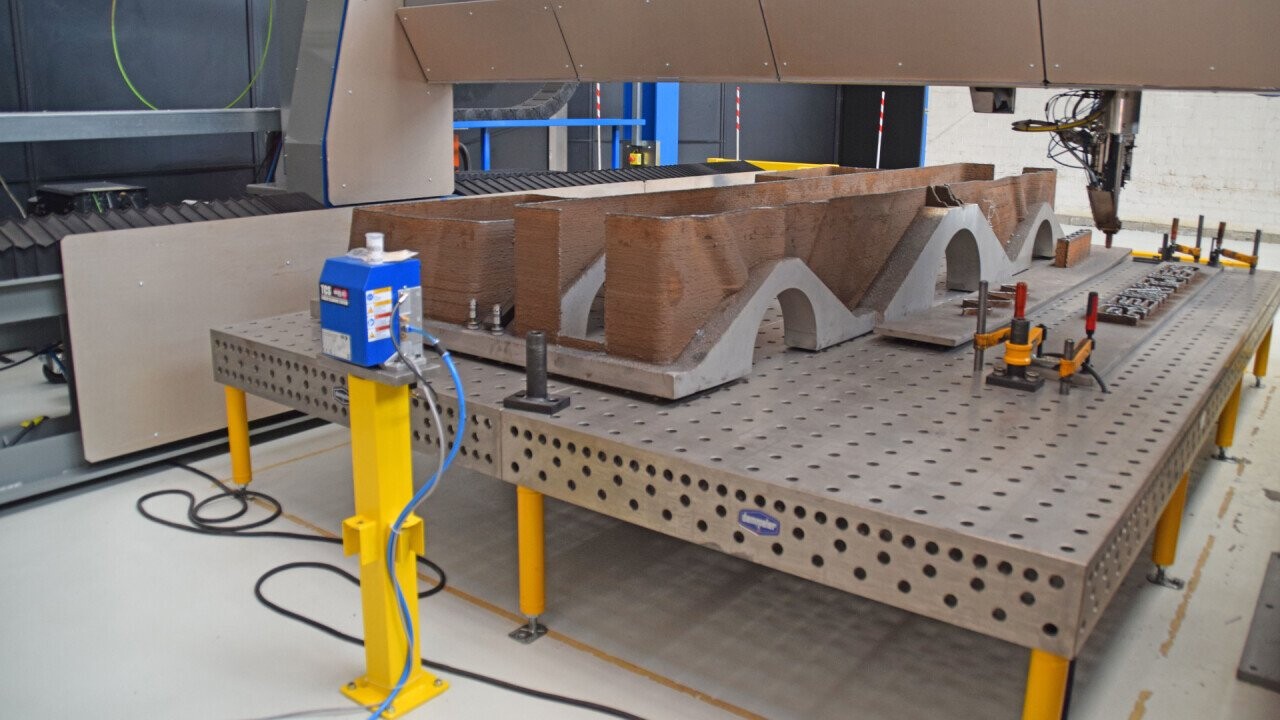

REINTJES has developed a demonstrator system in a research project. This system can be used to manufacture marine gearbox housings in an installation space of 4.5m x 3m x 1.5m. Laser-assisted arc deposition welding is used for this purpose.

Speakers (1)

Daniela Petra Haubold

Development engineer for additive manufacturing