ColdMetalFusion - 3D printing solution for electrolyzers

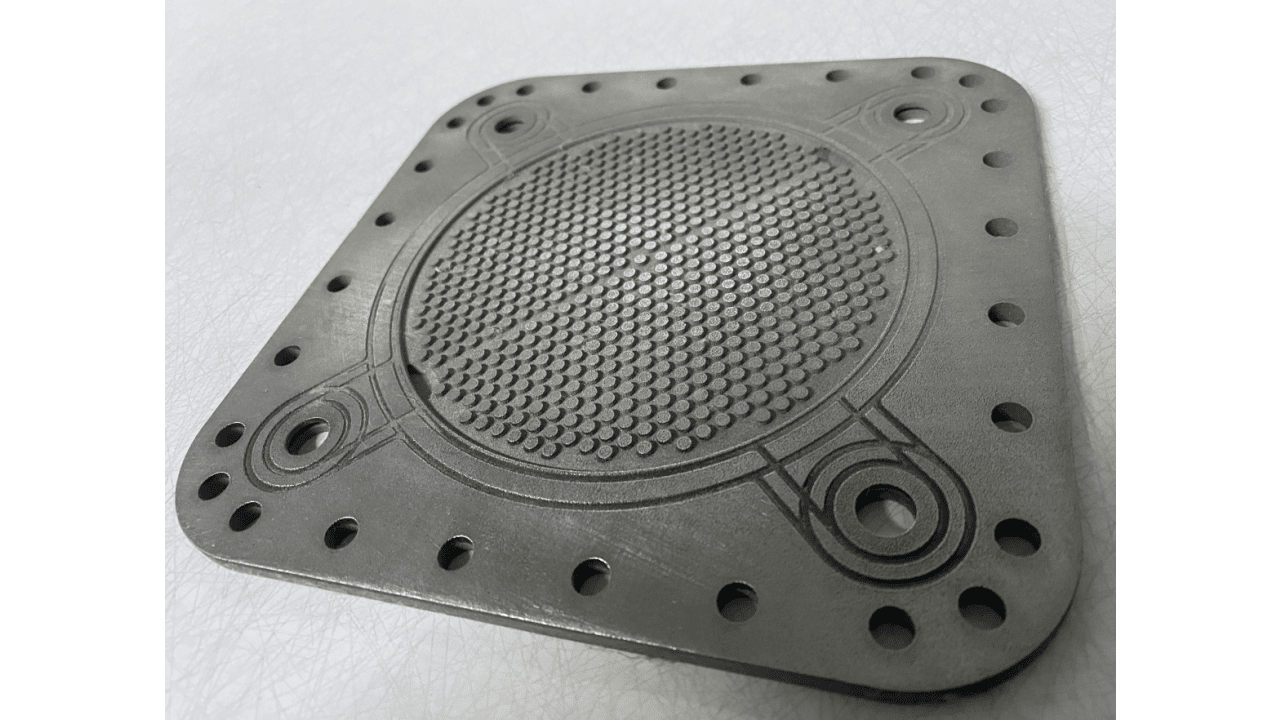

Bipolar plates are technologically and economically advantageous for the energy transition thanks to their production using ColdMetalFusion, a binder-based metal 3D printing technology.

Bookmark

Application of ColdMetalFusion technology for fuel cells and electrolysers

Additive manufacturing (AM) of metallic components is usually used for prototypes and small series. In contrast to other AM technologies, ColdMetalFusion (CMF) has been developed for use in series applications. This means that larger quantities can also be produced economically with CMF.

CMF can thus realize a shorter development phase for fuel cells and then be used directly for series production. The well-known AM advantages in terms of design optimization and function integration also apply to CMF.

In addition, CMF optimizes the entire process chain of a component, e.g. through the uniform surface roughness of all surfaces. Compared to LPBF, no support structures remain on the component after 3D printing. This is a particular advantage for the production of bipolar plates.

Presentation language: GER

Speakers (1)