High-pressure heat exchanger for hydrogen refuelling stations

In the transport sector, hydrogen is considered as one of the key solutions for reducing emissions - especially in terms of heavy duty vehicles. For fuel cell vehicles to become more widespread, a corresponding filling station infrastructure is required.

In the transport sector, hydrogen is considered as one of the key solutions for reducing emissions - especially in terms of heavy duty vehicles. For fuel cell vehicles to become more widespread, a corresponding filling station infrastructure is required. The conversion of conventional filling stations or the construction of new hydrogen filling stations requires complex technology, some of which must be integrated into the hydrogen dispenser. Due to the high pressure of the hydrogen during refueling, special requirements exist for the pressurized components.

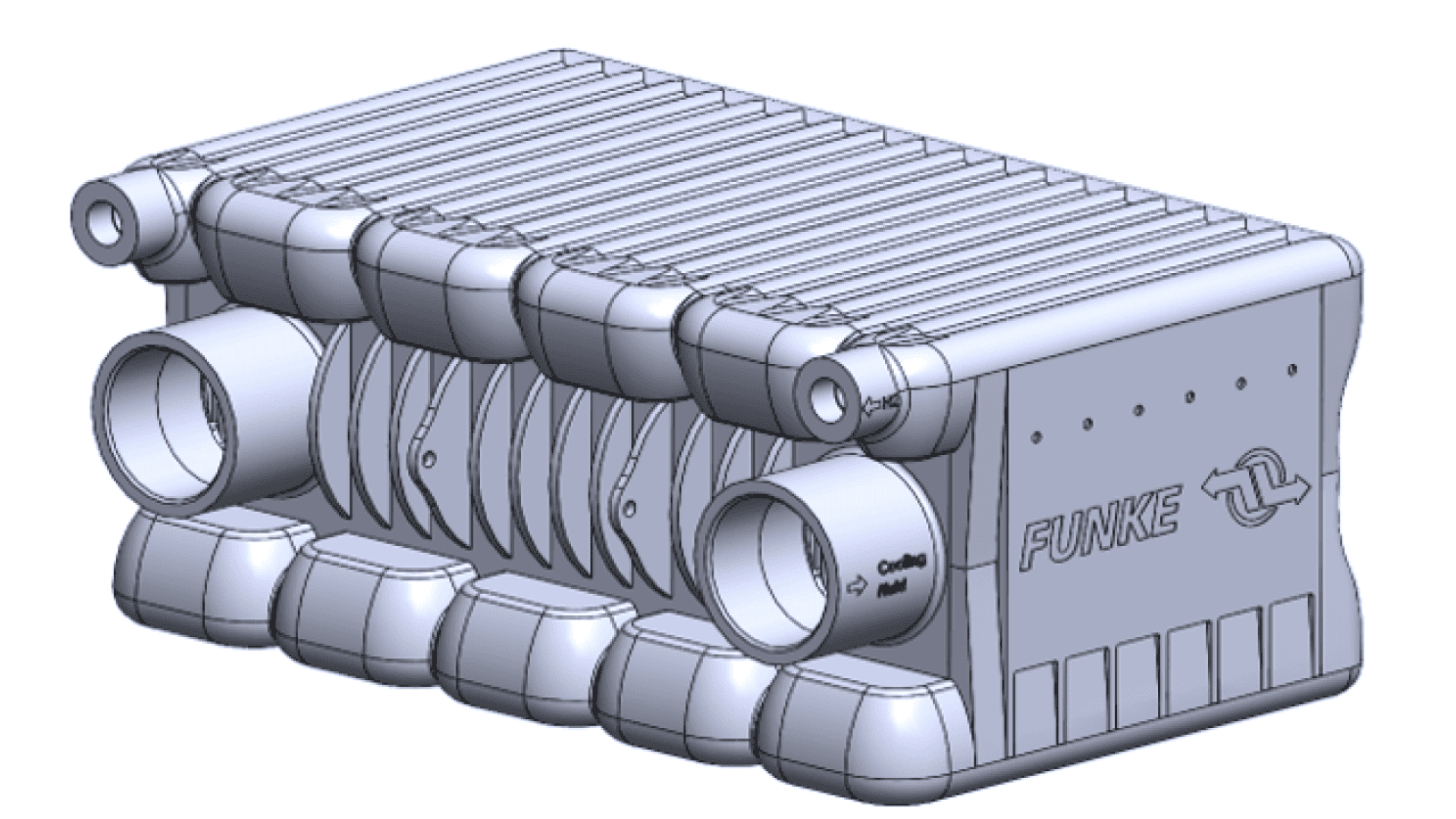

These components include the high-pressure heat exchanger required to pre-cool the hydrogen, which is being developed as part of the “AdekWat” joint project funded by the state of Lower Saxony. The Institute for Thermodynamics and the Institute for Product Development and Equipment Engineering at Leibniz Universität Hannover are involved in the project under the leadership of FUNKE Wärmeaustauscher Apparatebau GmbH. KSB is supporting the project as a certified manufacturer of additively manufactured components for pressure equipment.

The use of additive manufacturing technology (PBF - LB/M) allows additional geometric freedom in the design of the heat exchanger and contributes to the compact and lightweight construction. A modular design of the heat exchanger allows the device to be scaled and adapted to the available installation space.

The lecture presents the current state of development of the high-pressure heat exchanger and shows the challenges and solutions in the implementation of applicable regulations and directives, such as the Pressure Equipment Directive.

Presentation language: GER