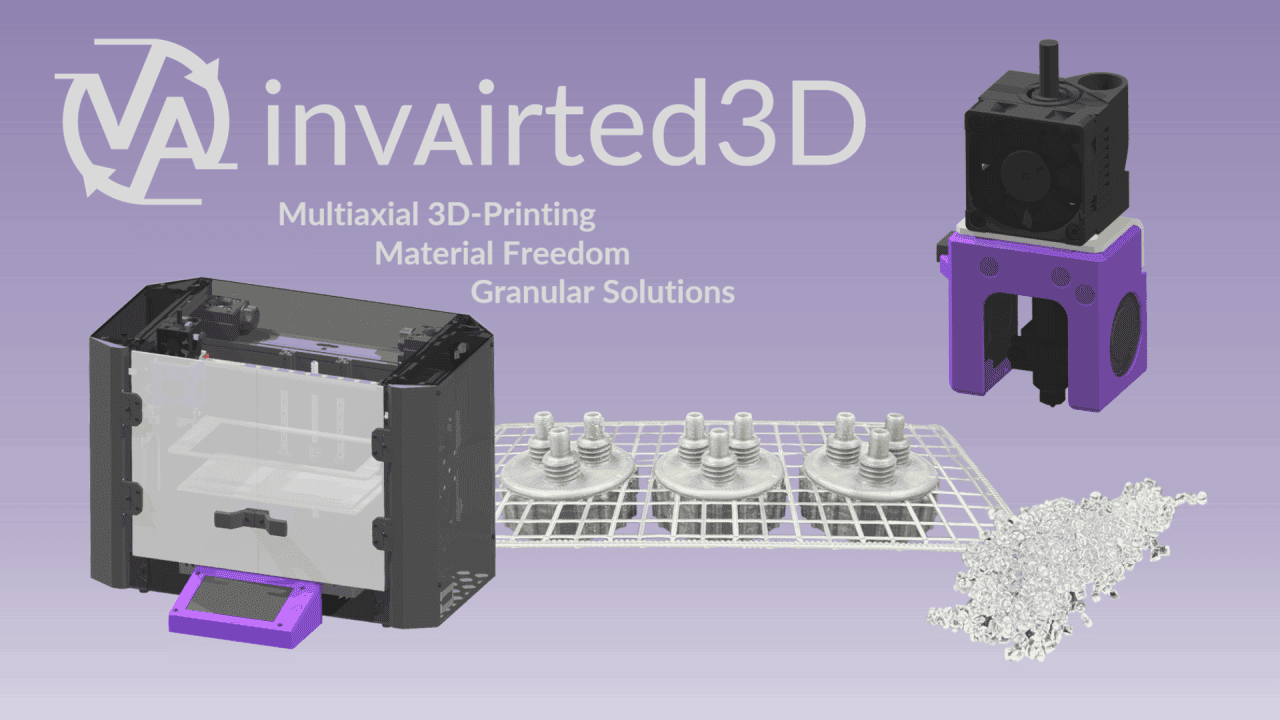

We have developed a cost-efficient multiaxial 3D printer based on the FLIPoQ process. We're also offering a lightweight pellet extruder including mini granules. This allows us to efficiently process even demanding and certified plastics such as PP, PC and PE.

Problem: Limited freedom of material and geometry

Extrusion-based additive manufacturing means that some plastic materials can only be processed to a very limited extent. The main reason for this are two problems.

Due to the material properties, there are problems with adhesion to the build platform, which means that some engineering plastics can only be additively processed to a very limited extent.

Another problem is the limited geometric freedom. Support structures are required for geometries with overhangs. These have to be removed after the manufacturing process, resulting in additional production waste.

These problems lead to further work steps, such as more intensive reworking or complex and cost-intensive machine technology.

Solution: Patented 5-axis manufacturing process FLIPoQ

With our patented 5-axis manufacturing process FLIPoQ, these fundamental problems of extrusion-based additive manufacturing processes can be eliminated.

By producing a new build platform in the form of a mesh, the material always adheres to itself. This mesh can be rotated, allowing the desired part to be generated from two sides. This saves a lot of support structures.

These capabilities make it easy to process any filament on the market.

Lightweight pellet extruder and mini granules as game changers

In order to be able to process even more materials, we also offer the multiaxial production system with a lightweight pellet extruder as a discharge unit. This makes it possible to process mini granules as well as standard pellets. This makes invAirted3D the first provider of mini granules in extrusion-based additive manufacturing.

With the help of the lightweight pellet extruder, it is possible to process any type of mini granules at a favorable price. Compared to conventional filament extruders, the small pellet extruder achieves a throughput five times higher of up to 500 g/h, which significantly shortens the process time. The mini granules can be individually color-matched and are more cost-effective than filament. Rejects can be simply and easily returned to the production process by regranulation.