Hydrogen and additive manufacturing in leading-edge engine technology – no contradiction

Hydrogen as a fuel requires several modifications on the engine in order to allow safe operation. One of these modifications is related to the intake manifold. An aluminium intake manifold is used instead of the typically used plastic part.

Bookmark

Upcoming, increasingly stringent greenhouse gas (GHG) limits demand for CO2-free propulsion systems. On the passenger car side, the current mainstream is seen in battery electric vehicles (BEV). Still alternatives are investigated and being demanded by various countries.

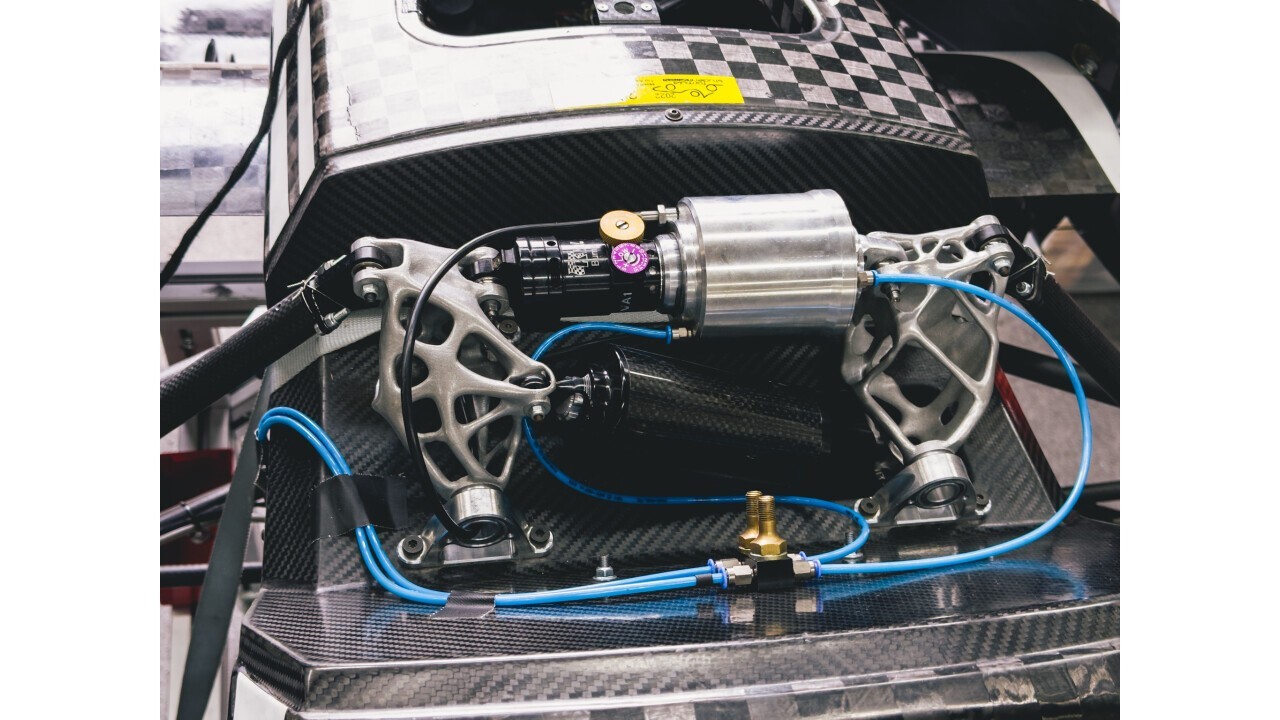

Hydrogen as a fuel requires several modifications on the engine in order to allow safe operation. One of these modifications is related to the intake manifold. An aluminium intake manifold is used instead of the typically used plastic part. The reason is the high reactivity of hydrogen – even small amounts of hydrogen in the intake manifold can lead to backfire events severely damaging a plastic intake manifold. In addition to this also the design of the intake manifold can required modifications. One reason is the integration of hydrogen or water injectors, another might be the use of low pressure EGR that requires an intake manifold design without dead areas that can accumulate condensate.

In the examples described 3D printed intake manifolds were used. This manufacturing method allows quick implementation of changes and quick manufacturing lead times.

To produce these components, selective laser melting (abbreviation SLM), also laser beam melting or powder bed-based melting of metal using a laser beam (abbreviation PBF-LB/M) was used.

The 3D printed parts were used in 2 engines: a highest performance hydrogen racing engine with a specific power output of 150kW/l and a “minimum changes approach” 1,4l passenger car size engine that was developed together with an OEM. The paper describes the 3D printed parts, the main engine features and some main results achieved.

Presentation language: GER

Speakers (1)