Components for molten salt reactors

Particularly in critical applications such as the nuclear industry, high-quality and reliable materials are essential. The molten salt in the reactors requires very high corrosion and temperature resistance above 500 °C.

Challenge

Conventional manufacturing processes quickly reach their limits when components with complex geometries are needed in this range.

Solution

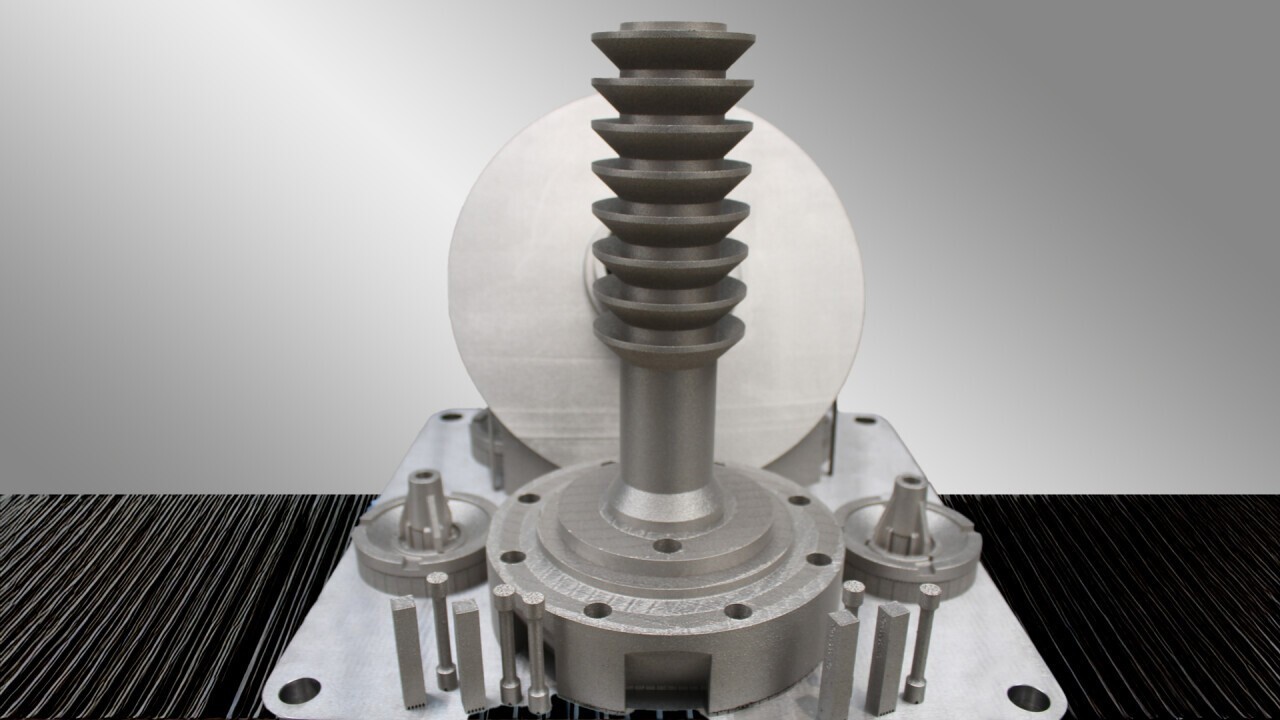

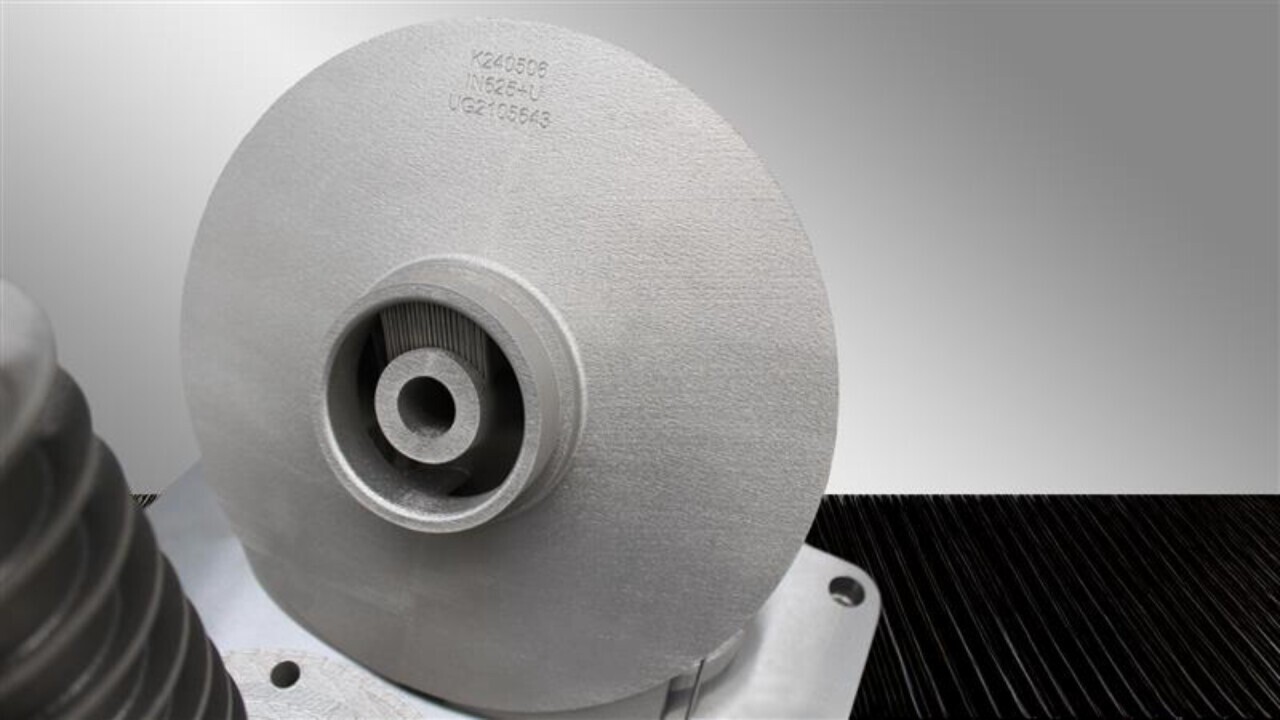

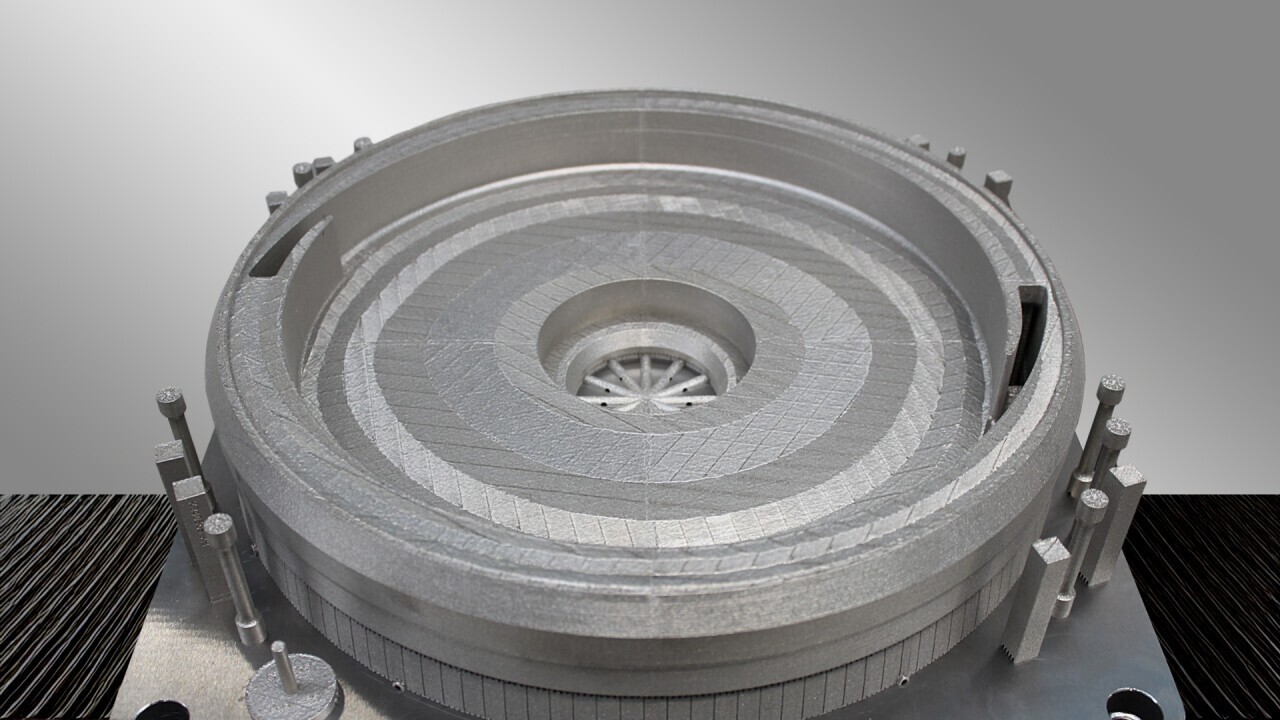

To ensure very high corrosion and temperature resistance, components were additively manufactured in Alloy 625 Grade 2. The 3D CAD data received from the customer was previously checked by KSB's specialist department and prepared for laser powder bed fusion. After successful simulation, we were able to produce pressure-retaining parts, rotating equipment and cooling inserts in accordance with the customer’s requirements.

Customer benefits

Thanks to years of experience and extensive testing processes in our materials laboratory, we were able to provide our customer with proof of the required corrosion and temperature resistance. We were also able to deliver the highly complex component geometries within a very short time.