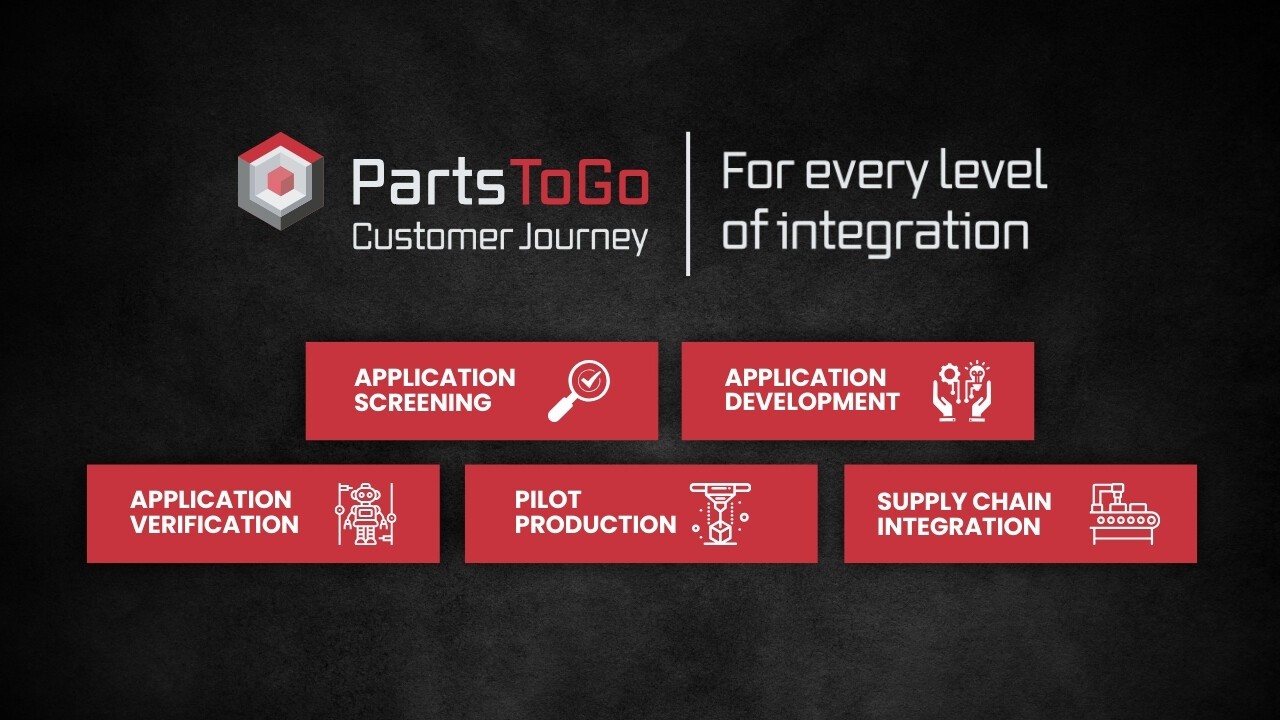

For every step of the integration – the customer journey at PartsToGo

Discover how PartsToGo supports companies step by step in integrating 3D printing – from the initial idea to series production. Benefit from customised advice and innovative solutions for your manufacturing!

It is now common knowledge that 3D printing has a number of advantages over traditional manufacturing methods. Whether it's speed, component complexity, production independence or much more, additive manufacturing offers invaluable benefits for companies and organisations.

However, taking the step towards this technology can seem daunting. The task of changing long-established structures and a certain rethinking in production planning, execution and control can be daunting for some companies, whether large or small.

Furthermore, it is not at all clear to some companies and institutions whether 3D printing can meet their requirements at all. Pre-produced sample parts, which are available from many service providers, can cover certain basic requirements, but when it comes to detail, they are simply not enough.

At PartsToGo, we recognised these difficulties in the integration of 3D printing when we were founded. That is why we, together with our partner company ProductionToGo, have not only dedicated ourselves to providing a simple service for component production, but also serve our customers and partners as an integral part of the full integration of additive manufacturing.

In this blog post, I would like to show you the steps we take to support our customers and partners and how they benefit from our collaboration. To provide a comprehensive overview, we will start with the support we can provide even before additive manufacturing has been verified for a specific application.

Phase 01 – Application Screening

Unlike other service providers, we don't expect a completed plan for every project, one that results in a complete digital model. We also sit down with potential partners who have had no contact with additive manufacturing to date and work with them to determine whether and how additive manufacturing can be used.

In this phase, which takes an average of one to two days, the focus is on discussing customer needs and expectations. Since every industry, every company and every application is different, it is of the utmost importance to us to know exactly what the requirements are for the respective components and potential production volumes.

The components and their properties are, of course, at the heart of this discussion. Weight, strength, flexibility, heat resistance, waterproofing, chemical resistance and many other characteristics that a component can exhibit are clarified and documented here.

Depending on the distance and the customer's preference, this discussion takes place either by email, telephone or in person at our offices and production facilities, where we can also directly present our production capacities, technologies and some sample parts to interested parties. But even in the case of discussions over distance, we ensure that we fully inform our potential partners about our options.

Once the fundamental requirements have been defined, our experts evaluate the fundamental feasibility of additive manufacturing for the respective project. We would like to be able to say that we can easily implement any project, but since we value the time and trust of our partners, honesty is our top priority. If something is not feasible, we communicate this clearly.

In most cases, however, we come to the conclusion that additive manufacturing and our production capacity are suitable for meeting our partners' needs. This automatically results in an initial pre-selection of technologies and materials, with the final decision only being made in the third phase.

Finally, our commercial experts prepare an initial cost estimate in this phase – and then the development and verification of the application can begin.

Phase 02 – Application Development

Once the application has been validated in principle and 3D printing has been identified as a suitable solution, we now have to implement the application step by step. Depending on the project, we plan between one and three months for this phase.

The first step in this phase is to define our partner's quality and performance expectations in more detail. This means that we jointly define key performance indicators (in the future referred to only as KPIs), which on the one hand enable us to refine our objectives and on the other hand enable our project partner to monitor the results more closely.

This is when the intensive development process for the application begins for us. The main focus here is on creating or adapting the design, compiling a selection of suitable technologies and materials, and precisely adapting the printing parameters to the project partner's requirements.

For this process, dedicated employees are selected from our group of companies and assigned to the project from the outset. In addition to our commercial specialists, these include experts in design creation and optimisation, as well as application development and implementation.

Over time, these experts develop increasingly precise project parameters. Starting with the creation or optimisation of the design and the selection of possible technologies, through to an ever-narrowing down of the material options and the selection of specific printers, and finally to the precise fine-tuning of the print settings.

Throughout this entire project phase, communication is our top priority. Our project partners should not be left in the dark for several months, but should be kept up to date and able to provide input throughout.

This input is not only beneficial to ensure that the project meets the requirements in every detail, but also potentially enables this phase to be completed more quickly. Since we provide the customer with a large amount of information material in this phase, e.g. material data sheets, the customer can use the information to exclude certain materials under certain circumstances, which simplifies our process and enables our partner to achieve faster results.

This project phase concludes with a final selection of potential technologies and materials. Together with our partner, we determine between one and two technologies, including suitable printers and a handful of materials, with which we will begin the third phase of the project.

Phase 03 – Application Verification

After application development, the focus in this phase, which lasts an average of one to two weeks, is on definitively verifying the process behind the application, making the final decision on technology and material, and providing our project partner with clear evidence that we have the ability to precisely implement their ideas in components.

This proof of capability is provided in particular by producing benchmarks with the technologies and materials that are still available for selection. These benchmarks are not just sample parts or prototypes for us, but always ready-to-use components or components of an assembly. These can be intensively tested by our partner for all the necessary properties, in order to verify the materials not only on the basis of a data sheet, but directly in the application.

If all the KPIs are met by the benchmarks, the final selection of technology and material follows. It is important to mention that it is never us, but always our partner who makes the final decision. Of course, we provide our expert opinion on the best possible choice, but if the customer decides on a different suitable material, for example, we naturally do not stand in the way of this decision.

We then carry out a final process optimisation in which a few details are improved. In doing so, we focus in particular on optimising costs for the customer, for example by trying to minimise material waste or, if polymer powder is used, to increase recycling rates.

While our application experts are putting the finishing touches to the application, our commercial experts are working on the final cost estimate. This includes both the costs that would arise if we were to provide a service and the TCO (total cost of ownership) if the customer were to purchase the machine selected for the project in order to implement the application in their own production facilities at a later date.

Phase 04 – Pilot Production

Once the component verification has been completed, or in the case of an already developed application, the customer has chosen us as a partner, the aim of this phase, which lasts between one and two months, is to establish both additive manufacturing and our production capacities as a long-term solution.

To do this, we produce a small or medium-sized series, depending on the complexity and size of the components, and send it to our partner. This allows them to get to know our entire process, from ordering to shipping, and to check the repeatability and consistent quality of our process.

Communication between us and our partners is also an essential constant in this phase. Whether it's last-minute changes or specific requests, a dedicated expert is available to each of our partners to take care of their concerns.

While we take care of production, it is time for the project partner to decide towards the end of this phase on one of our two options for fully integrating additive manufacturing into their production process. Either continue to use us as a service provider, or use our parent company ProductionToGo with its own machine.

Of course, experts from both us and ProductionToGo are on hand to provide you with active support in making this decision. As soon as the decision has been made, the project enters its final phase – the integration of additive manufacturing.

Phase 05 – Supply Chain Integration

Integration via PartsToGo

If customers decide to continue to use us for their 3D printing production, the integration phase is of course much shorter than if they first have to install their own machine, due to the previous phases via us, in particular the pilot production.

The most important steps in this phase are, on the one hand, the definition of quality via specifications and, on the other hand, the establishment of a clear and precise cost and time structure for future production runs.

Once these minor organisational hurdles have been overcome, we can immediately set about a further production run. With capacities of up to 1,000,000 components and a large team of experts, we ensure high-quality components with on-time delivery in this phase, thus offering a partnership based on reliability and honest communication that allows you to implement your production with ease.

Integration via ProductionToGo

If the decision is made to adopt the process into your own production, the first step is to find the optimal way to integrate additive manufacturing and its advantages into your production without completely overhauling existing structures.

To do this, the application experts from ProductionToGo sit down with the project partner to find an ideal solution. Due to the individuality of each production plant, this process cannot be described in general terms, but we estimate that it takes about one to two months to include all eventualities in the integration.

This is followed by the installation of the system and intensive training for the users. In the process, the employees are familiarised step by step with the machine and the associated software and gain an intensive insight into our production process and our printing parameters, so that our project partners can implement the process ideally at their own site.

Even during in-house production, ProductionToGo remains at your side as a reliable partner. Whether it's advice and support during production, maintenance and repair of the machine, supply of consumables or further process optimisation – together we ensure maximum efficiency in your production.

With Additive Automation GmbH, another part of the Neck Enterprise, there is also the option of automating your 3D printing production. Our V1 production cell enables almost contactless production and post-processing of your 3D-printed components, so that there is no downtime even during holidays and at night.

And of course, our services are still available. Whether it's backup production in the event of unforeseen downtime or add-on production to meet sudden production peaks, we make sure you can strike the word ‘downtime’ from your business lexicon.

Conclusion

Comprehensive service is our daily business. Our goal is to help companies that have had little experience with 3D printing so far to reap the benefits of 3D printing – for a future-oriented and sustainable industry 4.0.

If you, like many of our other customers, are looking for maximum expertise in 3D printing integration, then visit our experts at Rapid.Tech 3D at Booth 2-109. We will be happy to advise you individually on your requirements and find the best way to integrate additive manufacturing into your production.