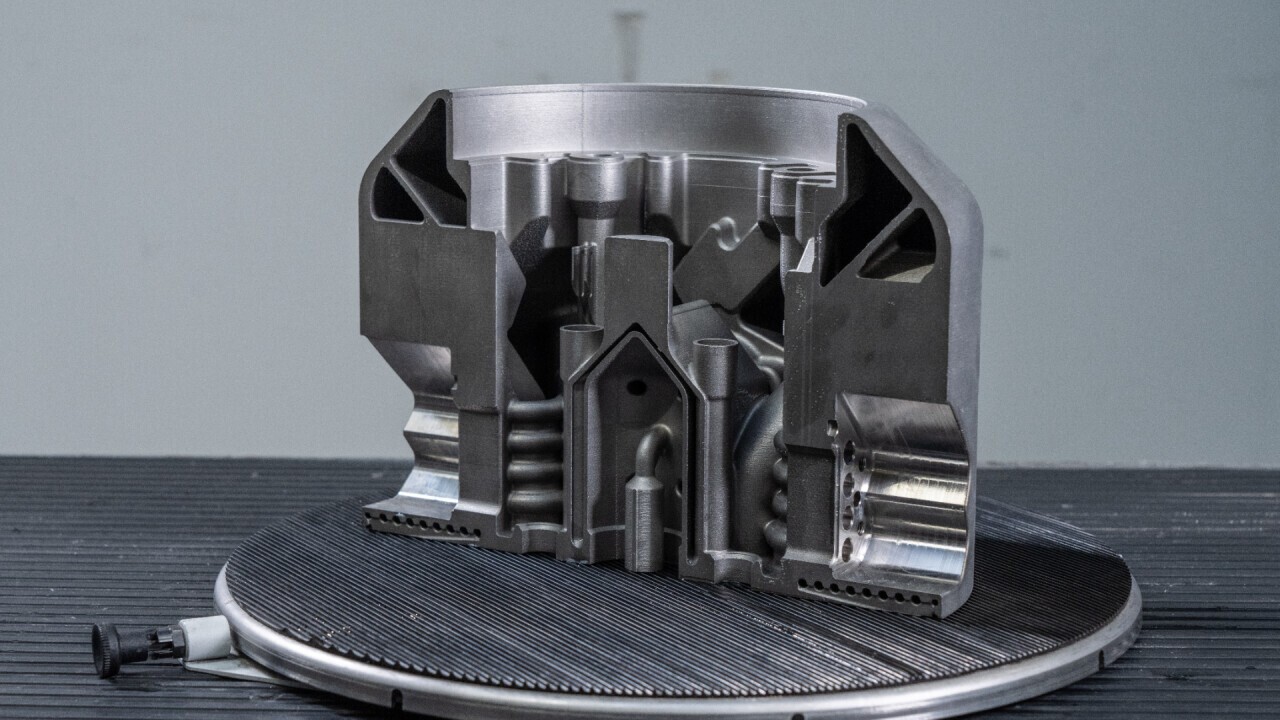

Special components for complex installation situations

Difficult installation conditions are not unusual in special-purpose machines. Special solutions are often required, for example components with complex geometries and/or in high-alloy materials.

Challenge

However, the small quantities involved result in high costs – and procuring special materials makes the project even more challenging. Special geometries are often the only solution for particularly narrow and problematic installation spaces.

Solution

Additive manufacturing processes enable parts to be produced as a single piece, i.e. without joints. Reducing the number of production steps also reduces the procurement time.

Customer benefits

Through additive manufacturing we can significantly reduce costs, particularly with high-alloy materials. The reduction in production steps also means a reduction in delivery times for our customers.

On request, our customers receive 3.1 or 3.2 certificates to EN 10204 as proof that the material meets the agreed specifications.