Additive Manufacturing for Next-Generation Microelectronics

The audience will learn how additive manufacturing in microelectronics enables the fabrication of next-generation devices that are smaller and more efficient, while also allowing greater design freedom.

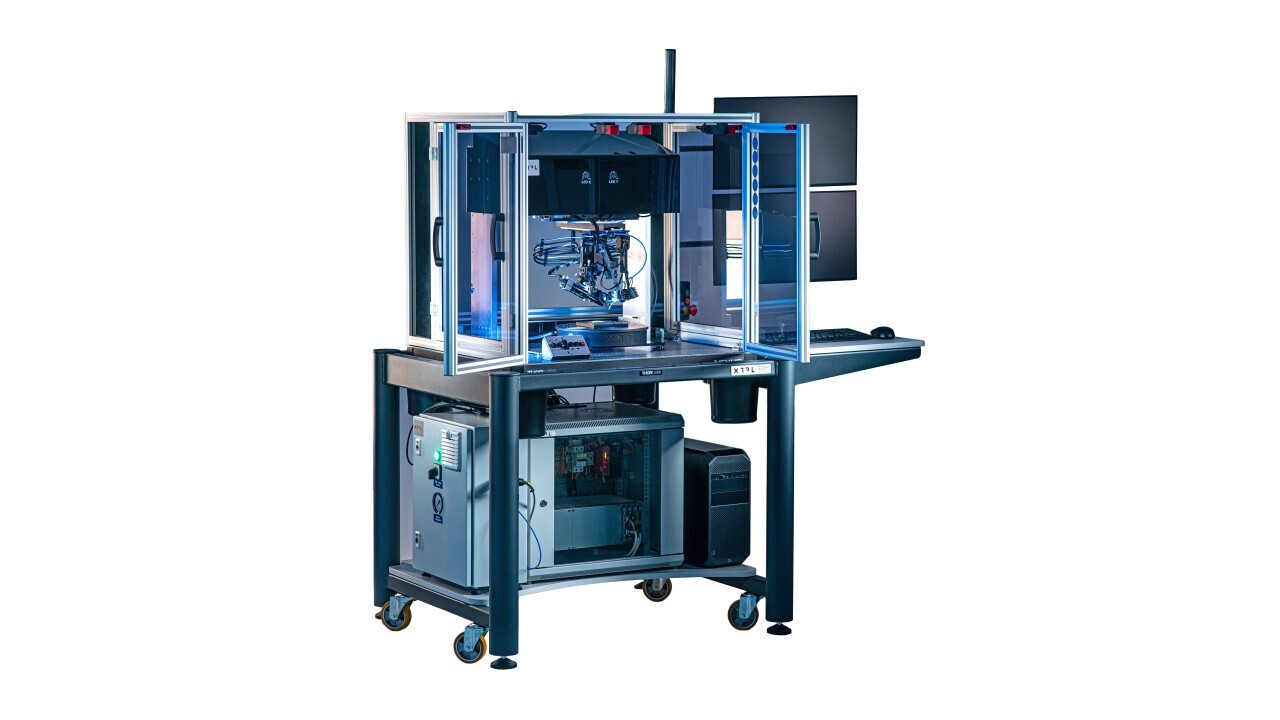

The miniaturization of electronic components and the demand for higher integration density require new solutions in additive manufacturing. XTPL’s Ultra-Precise Dispensing (UPD) technology allows for high-resolution, direct-write deposition of conductive and insulating materials at the micron scale, providing an alternative to traditional wire bonding. UPD can print features as small as 1 μm using high-viscosity inks, including nanoparticle-based metallic pastes. It operates without electric fields, making it compatible with sensitive devices and various substrates, both rigid and flexible, as well as 3D topographies.

XTPL’s maskless printing platform enables the creation of advanced microelectronic structures, such as redistribution layers, fine-pitch interconnects, high-frequency antennas, and flexible sensors. Its capability to work with high-viscosity materials and complex 3D surfaces supports a wide range of applications, from advanced packaging and display manufacturing to printed electronics. By eliminating the need for masks and reducing material waste, it simplifies microfabrication processes while maintaining high precision and allowing greater design freedom. With its unique capabilities, UPD offers a scalable path from R&D to manufacturing for additive solutions in microelectronics.

Presentation language: EN

Speakers (1)